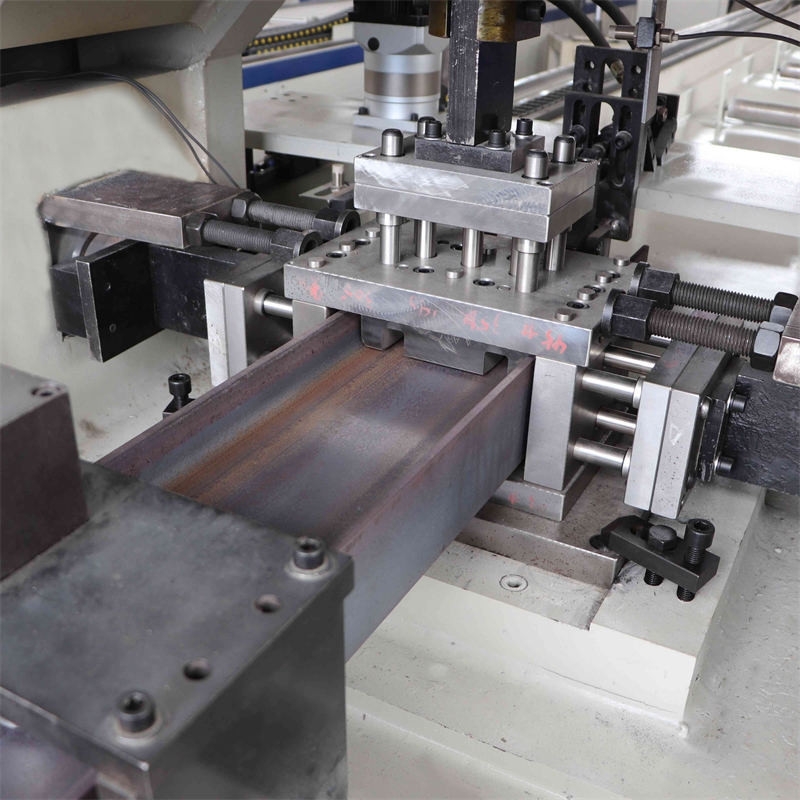

CNC H-Beam Punching Machine

LETIPTOP CNC H-Beam Punching Machine mainly do the punching process of the H-beam and I-beam which used widely in pallet rack systems, steel structure, iron tower, bridge, and machining industries etc.

●H-Beam / I-beam Punching

●H-Beam / I-beam Punching

●Web and the flanges punching

●CNC controller for hole distance punching programming

●The Max. length of beam upto 12 meters.

Description

Description

Making holes in H-beam is very time consuming – LETIPTOP has a way to change that. With LETIPTOP’s CNC H-Beam Punching Machine, it is quite easy to fulfill the punching process for flange and web of H-beam in one run. LETIPTOP CNC H-Beam Punching Machine mainly do the punching process of the H-beam and I-beam which used widely in pallet rack systems, steel structure, iron tower, bridge, and machining industries etc.

CNC H-Beam / I-beam Punching Machine Features:

●Fully automatic H Beam Punching.

●Automatic feeding, clamping, punching.

●It consists of flange punching units and web punching unit.

●It is able to punch 3 or 9 different hole shapes in 3 different directions.

●Three cylinders 3 independent punching units: from top, left, right.

●It can fulfill the punching process for flanges and webs of H-beam, I-beam in one run.

●The distance from hole to beam end, the distance between holes are controlled by servo motor.

●Servo motor and PLC can assure the punching positional accuracy.

●Electric servo feeding over linear guides for highest precision.

●Gear rack by high-frequency grinding and heat treatment.

●Silent motor oil pump for automatic cooling.

●The tank chain is more durable which used to precisely drive the steel plate.

●Collecting tray for punch remnants for easy daily maintenance.

●automatic feeding conveyor system

●Back Pulling System (combined with Servo Motor): To pull the H-beam from the other side by the another Servo Motor for punching the last hole which is too close to the H-beam end(Option).

●Touch screen controls for file management and editing (feeding length, quantity, punch tooling)

●The engineer can operate easier without programming experience.

●SHK-51 high-speed steel mould.

●The hardness of the molds up to 53HR.

●50,000 times for non-destructive punching. More than 300,000 for punching life.

●The main mechanical, hydraulic, electronic parts adopts global brand.

●The machine body welded by steel pipe and iron plate, and the overall precision machining by large gantry CNC machining center.

●The whole machine are integrated designed, don’t need to lay the foundation.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the CNC H-Beam / I-beam Punching Machine and talk to LETIPTOP expert.

Technical Parameters

.jpg)

Configuration

.jpg)

Workpiece

Workpiece

.jpg)

.jpg)