Description

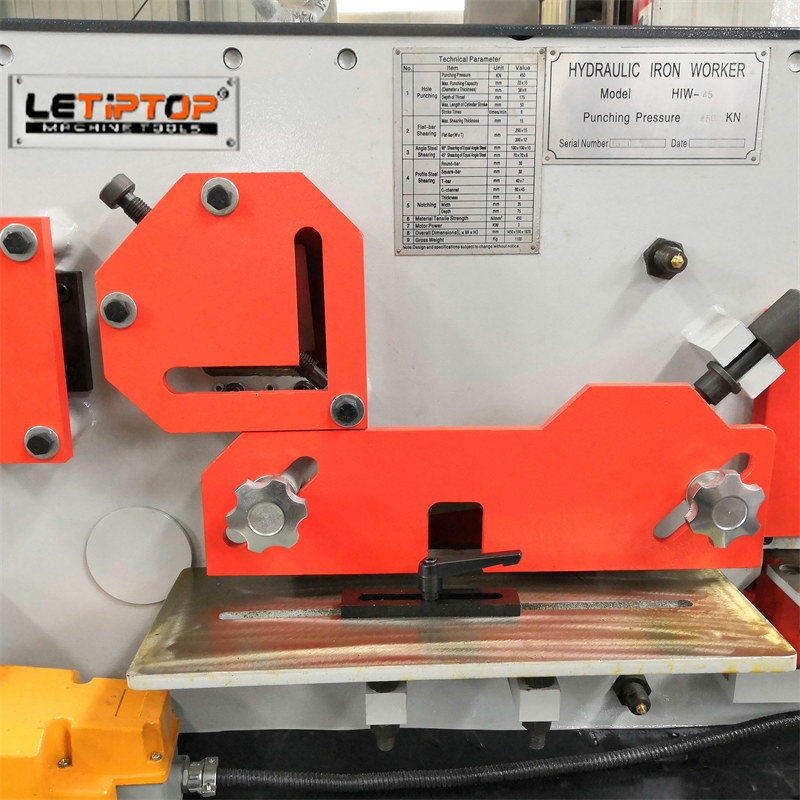

Single Cylinder Hydraulic Ironworker Description

This is single-cylinder pivoting-type Hydraulic Ironworker with five working stations. It contains almost all the functions you would like to punch, cut and notch. We can make it with single-phase voltage for home use. It can also be used as a three-phase voltage for workshops. It is a very practical and universal Hydraulic Ironworker Machine.

Single Cylinder Hydraulic Ironworker Features

●45 tons Ironworker for punching and shearing.

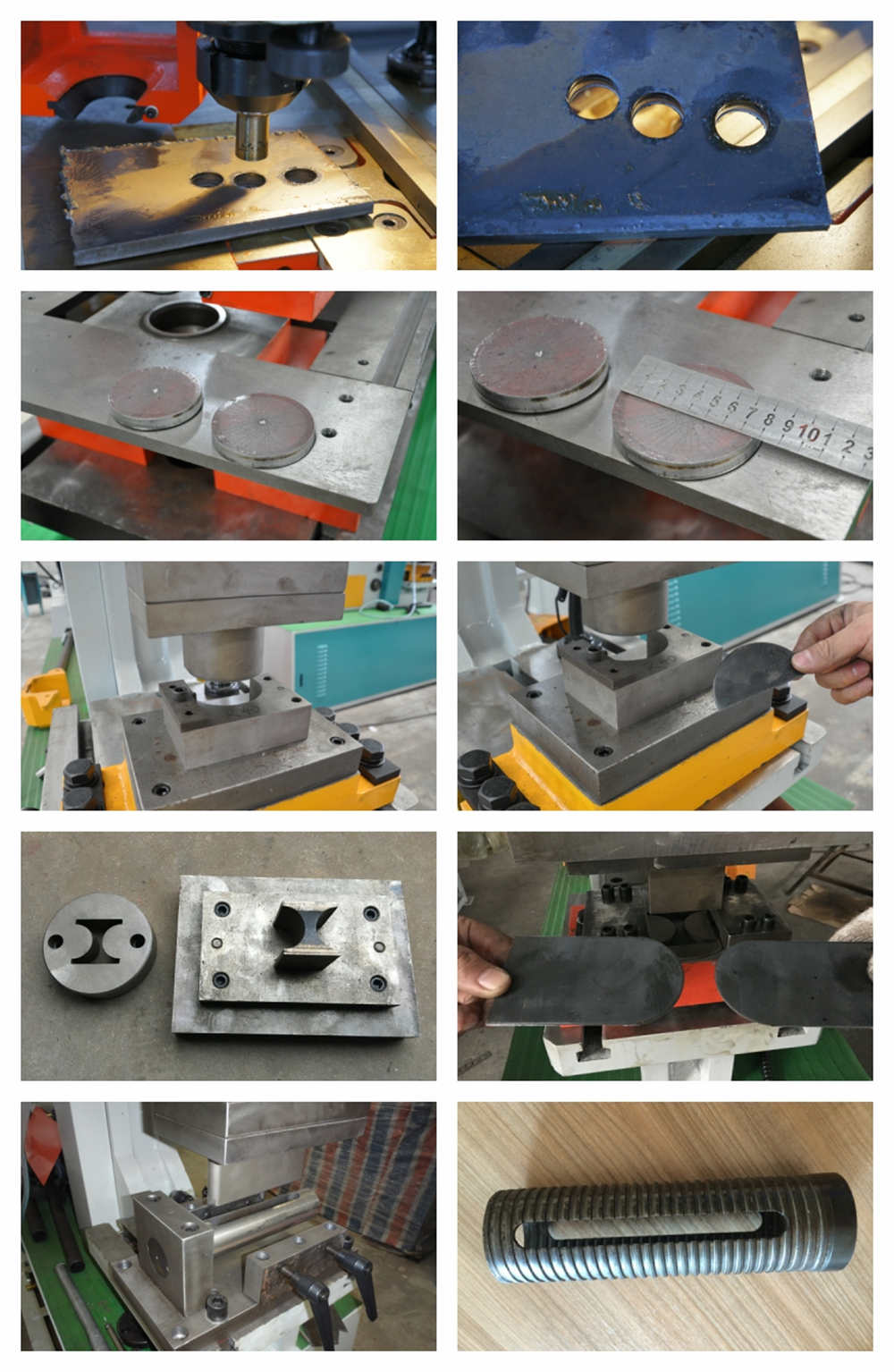

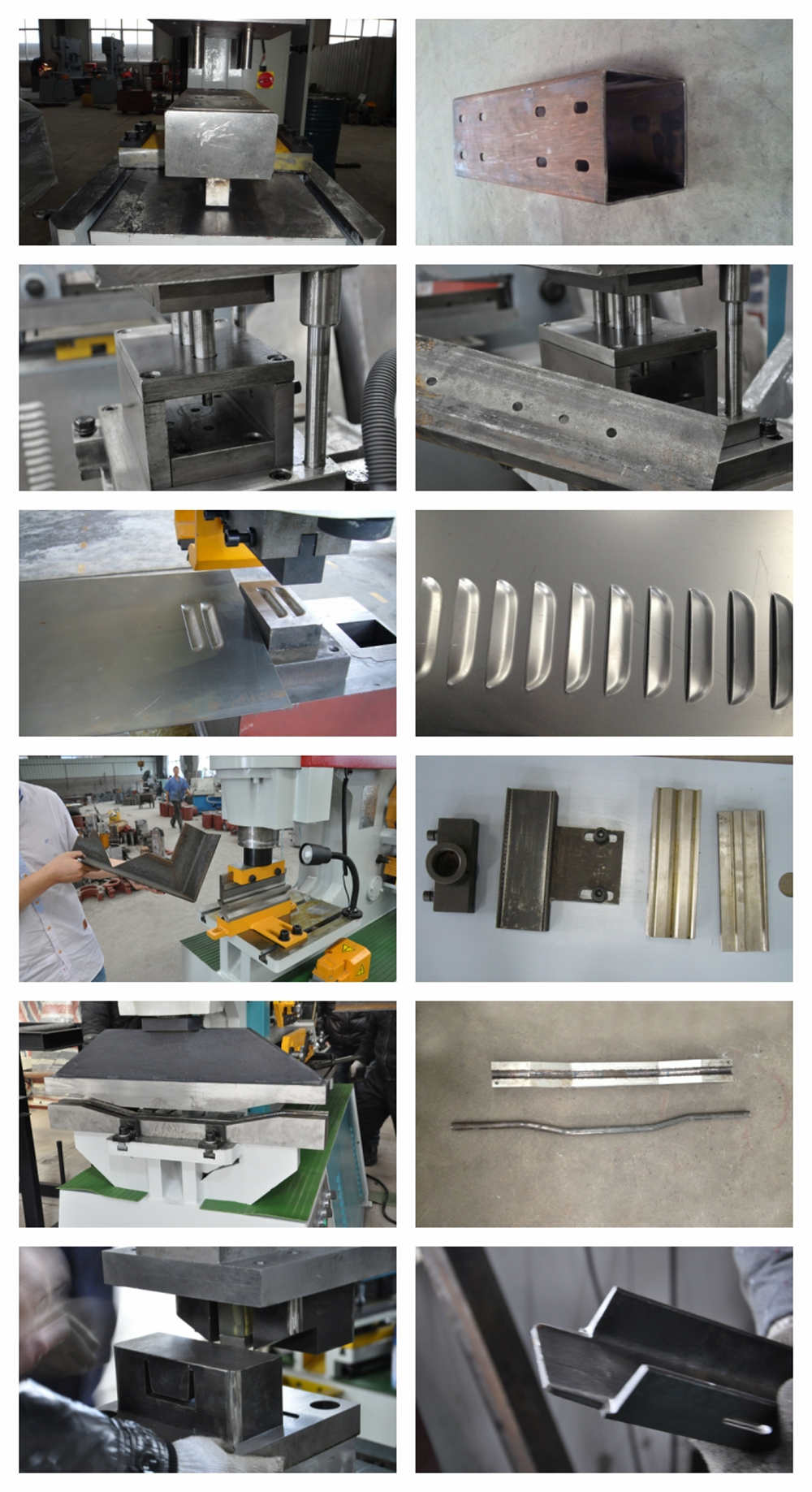

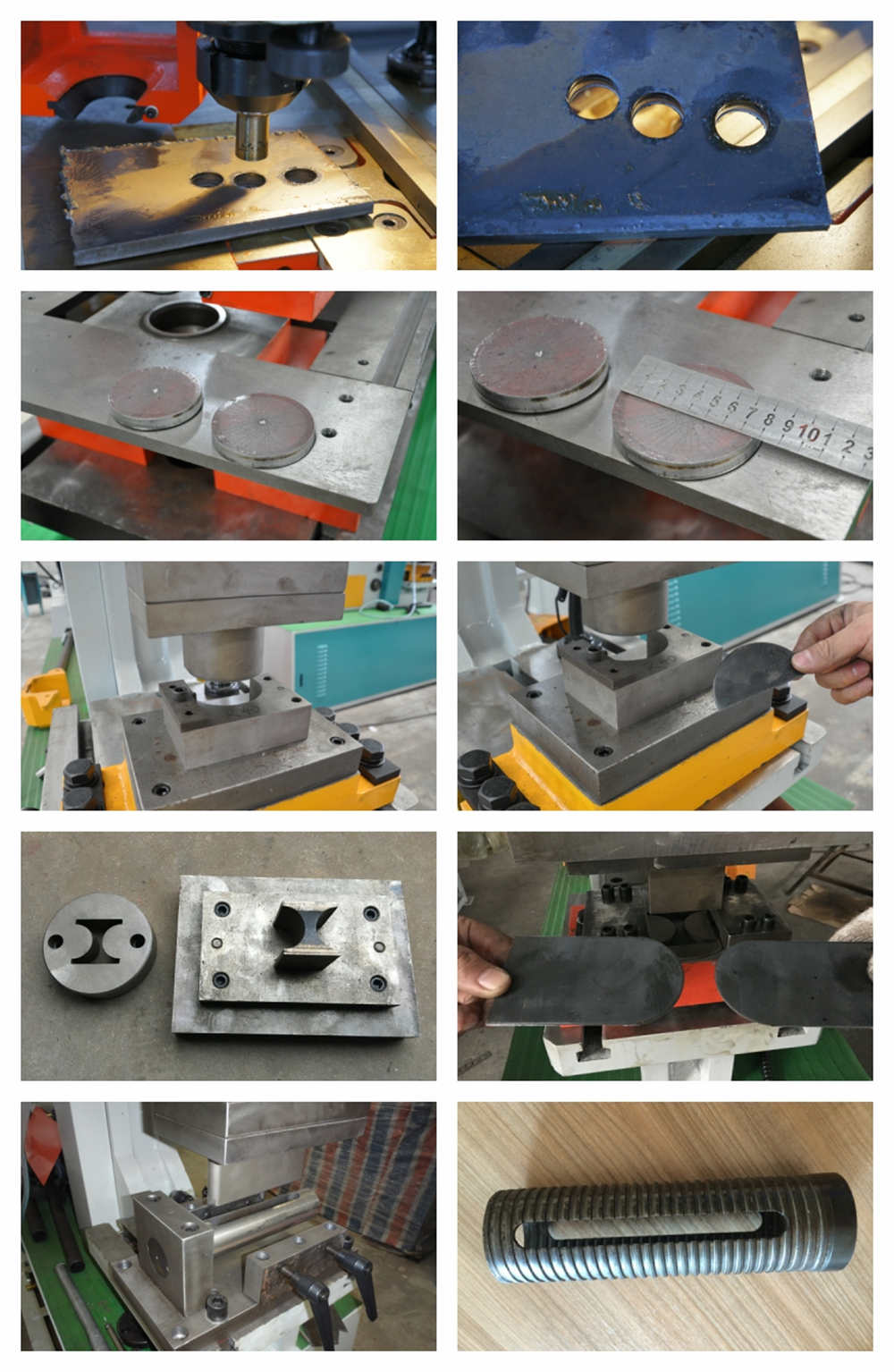

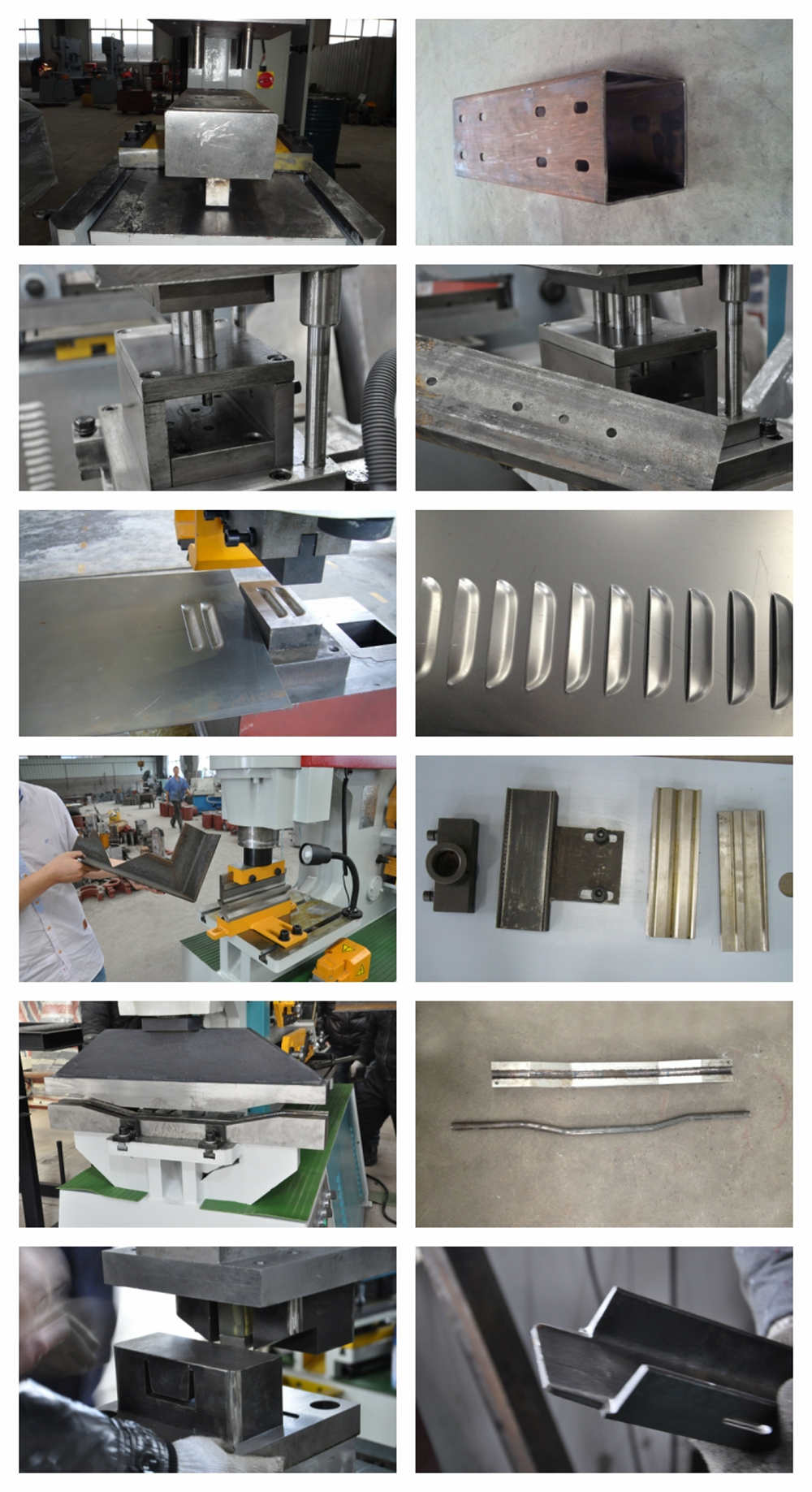

●5 working stations which including hole punching, angle steel cutting, round& square bar cutting, flat bar shearing and notching.

●Square hole, round hole, oblong hole, and other shaped holes can be punched after changing the punch and die.

●The profile cutting station can also cut C-channel, I-beam, H-beam, T-bar and so on.

●The detachable working table can be punched angle steel in addition to the flat plate.

●Work efficiency can be improved by adjusting the stroke of the punching and shearing station.

●You can punch and cut up to 22 times per minute.

●1-meter automatic back gauge for control the cutting length of sheet plate and profile steel.

●The footswitch is designed in the middle of the machine and can be moved to various stations for easy operation.

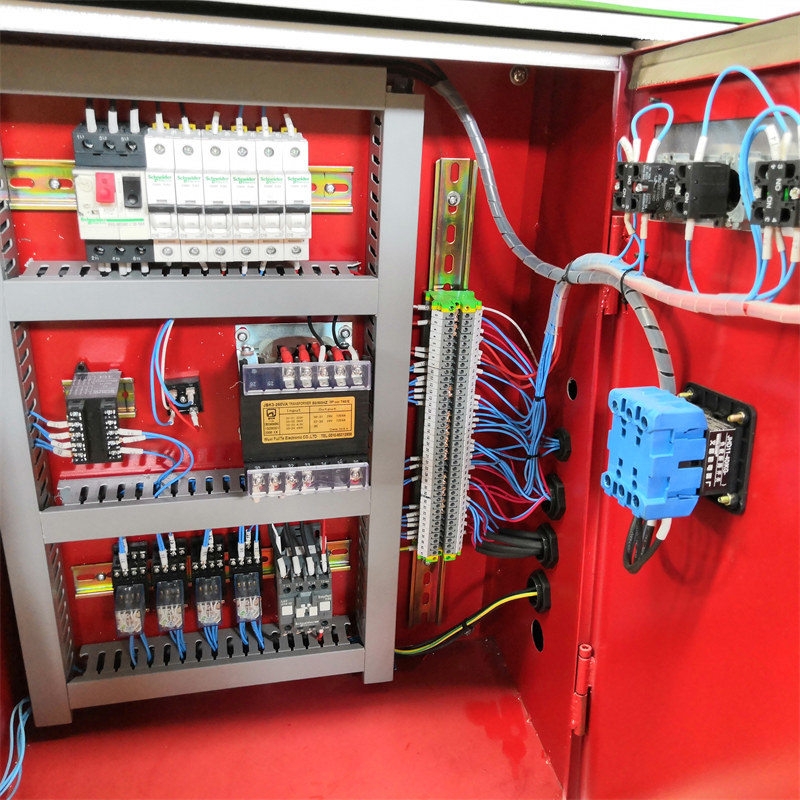

●LETIPTOP has always been committed to the safety of the machines, with an emergency stop switch on the machine’s electrical cabinets and working stations. At the same time, safety point is installed in the notching station. If you open the safety shield for non-safe operation, the machine does not work.

●LETIPTOP offers optional molds such as pipe notching and sheet plate bending attachments to make the machine more versatile.

●Heavy-duty welded steel construction maintains precision, minimizes machine body bending and maximizes machine life.

●2 years warranty and lifetime technical support.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the Hydraulic Ironworker and talk to LETIPTOP expert.

Technical Parameters

.jpg)

Configuration

.jpg)

Workpiece

Workpiece

.jpg)

.jpg)

Model Selection

Model Selection

Formula:

TONNAGE = (perimeter x thickness x strength)/1000

P=CxTxS/1000

P-punching pressure (Tons)

C-perimeter (mm)

T-thickness (mm)

S- material strengths(kg/mm2)

Material Strengths:

Mild Steel: 38 to 52 kg/mm2

Stainless Steel: 85 kg/mm2

Copper: 22 kg/mm2

CAUTION: Never punch a diameter smaller than the material thickness.