Heavy-duty Hydraulic Ironworker Machine

Description

Double Cylinder Hydraulic Ironworker 200-400T

In order to meet market demand. So, LETIPTOP has designed heavy-duty Hydraulic Ironworker, which capacity range from 200– 400 T.

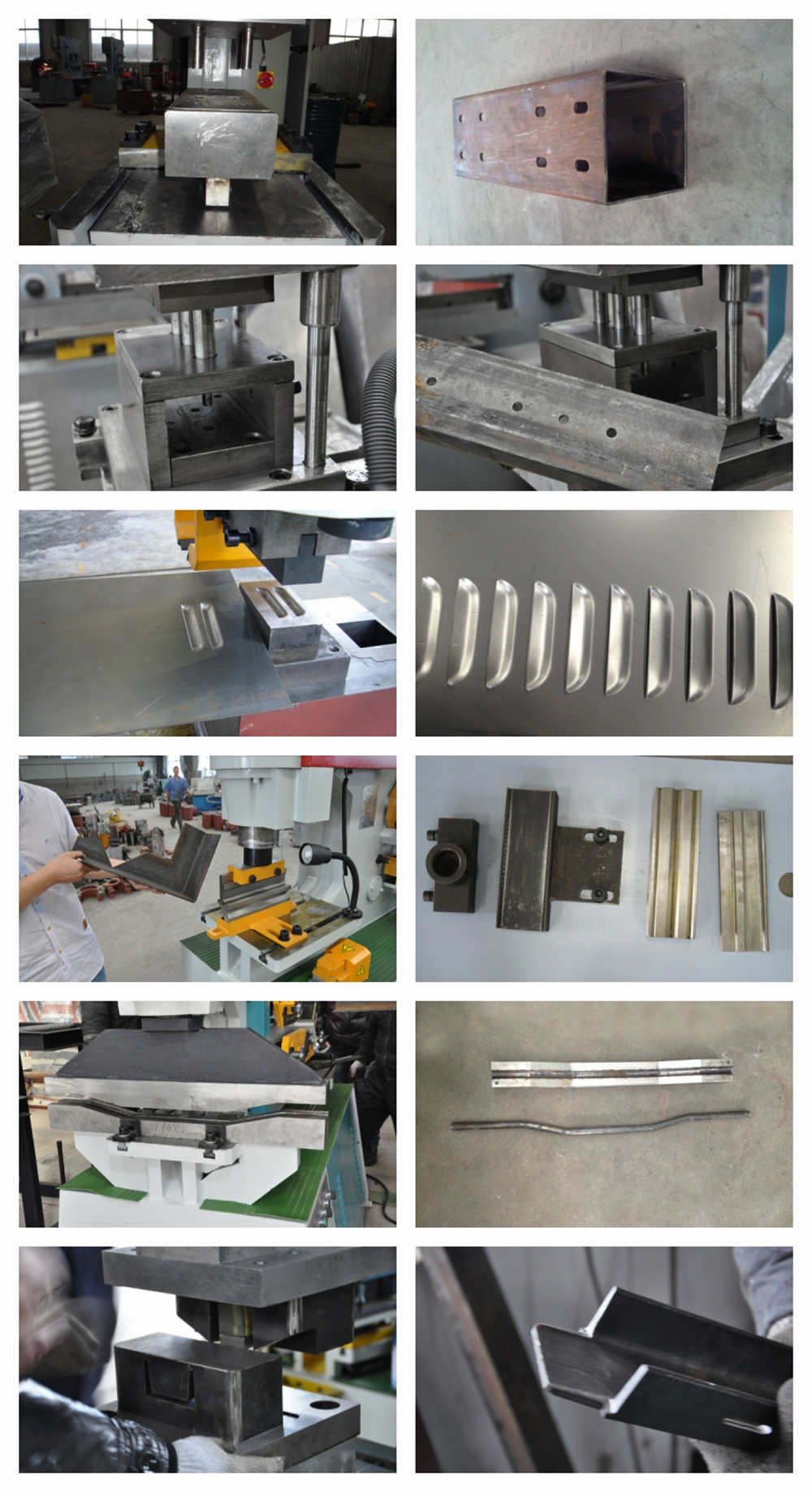

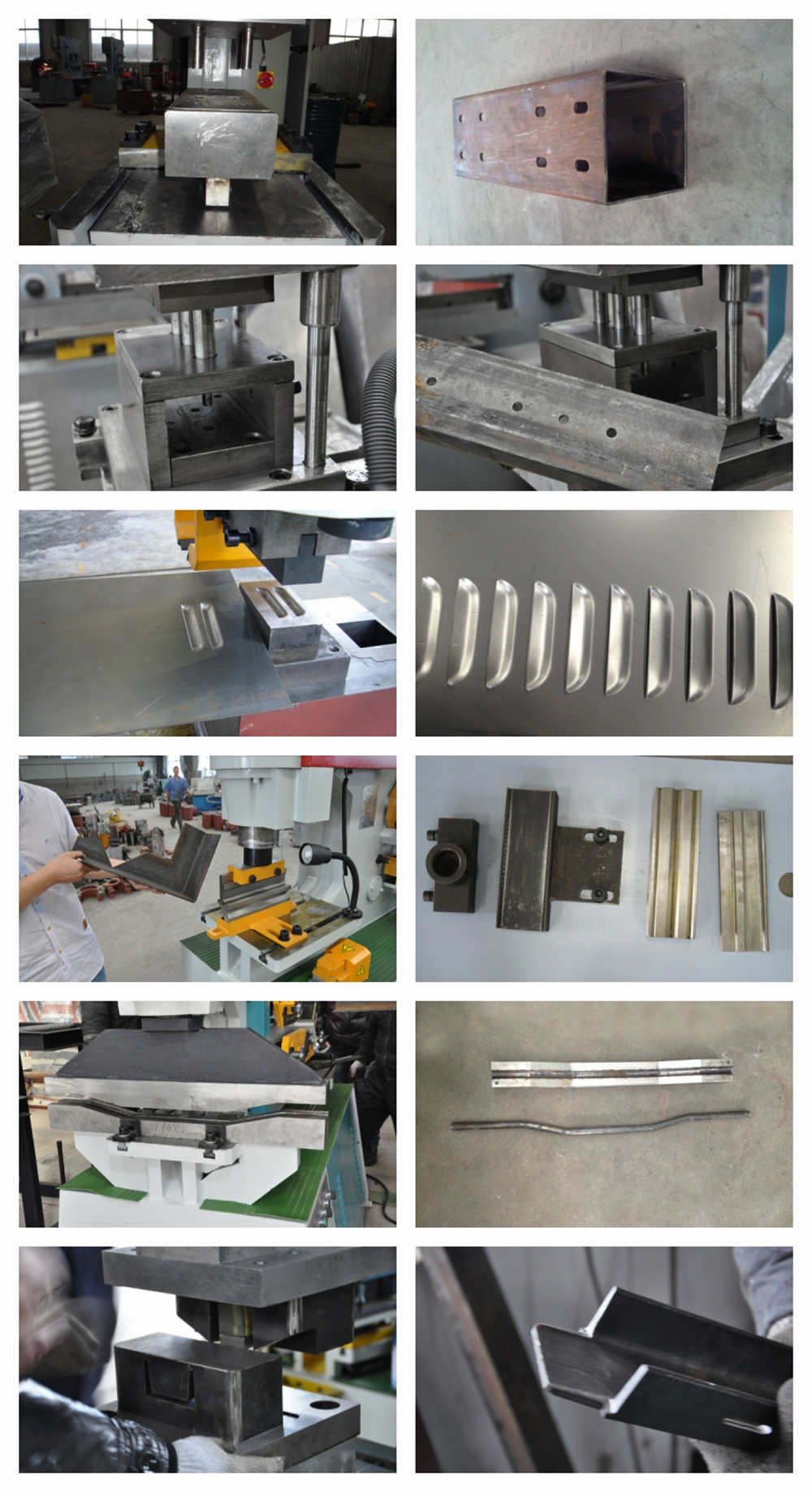

Yes, it is right. It is Max 400 tons of Hydraulic Ironworker Machine. LETIPTOP designed and produced the world’s largest capacity of Hydraulic Ironworker Machine. steel structure processing, bridge, high and low voltage towers, and wind power towers are wide use. in addition, is mainly used for shearing and punching of steels such as C-channel, square bar, round bar, and I-beam and H-beam.

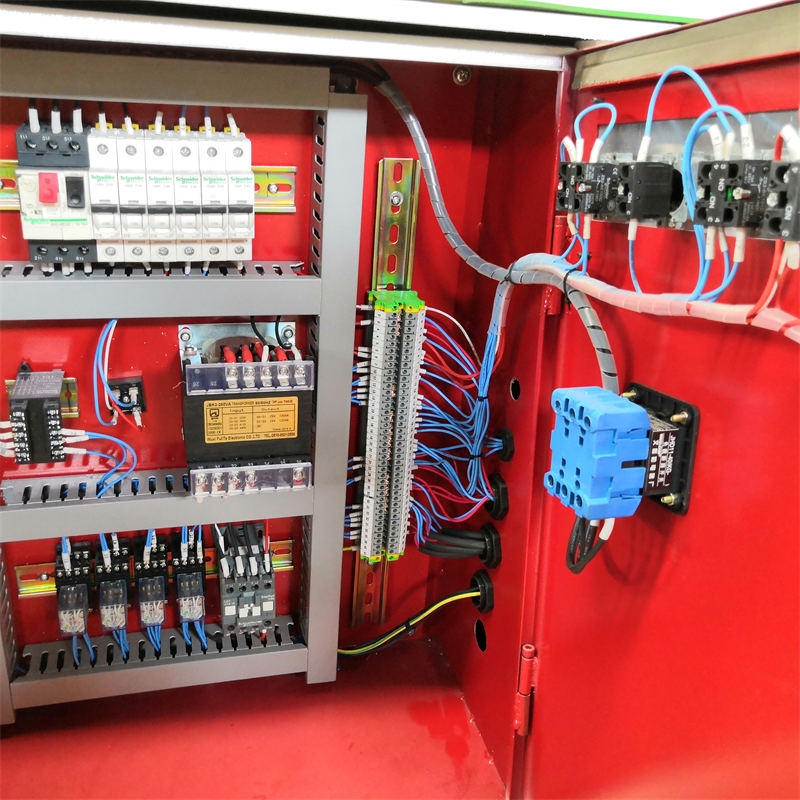

LETIPTOP has always been committed to the safety of the machine, so using our Hydraulic Ironworker Machine can greatly reduce the loss caused by workers’ work injuries.

All LETIPTOP machines have low noise levels to avoid damage to the eardrum of workers.

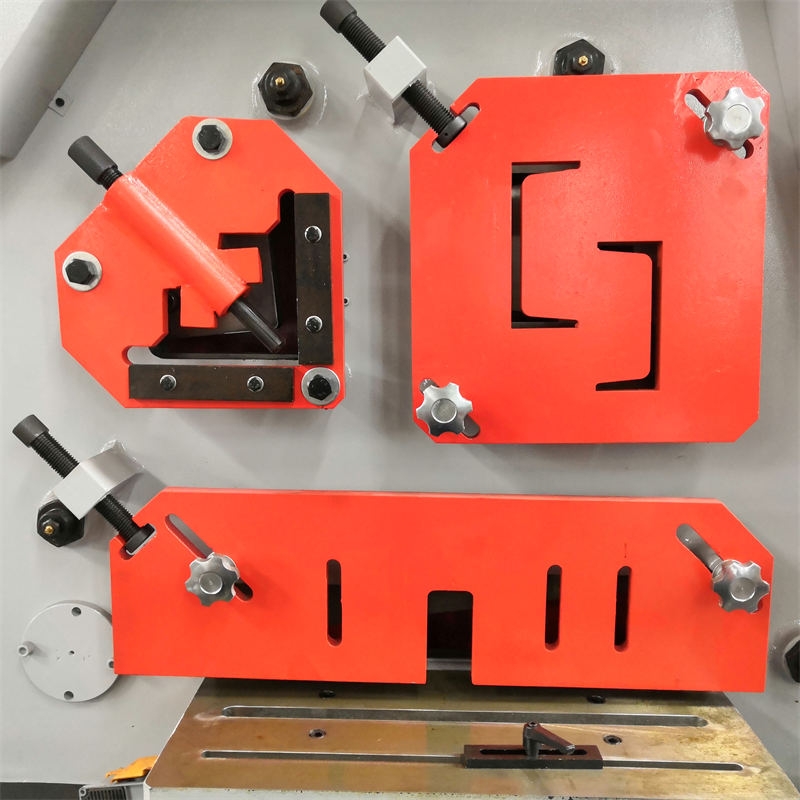

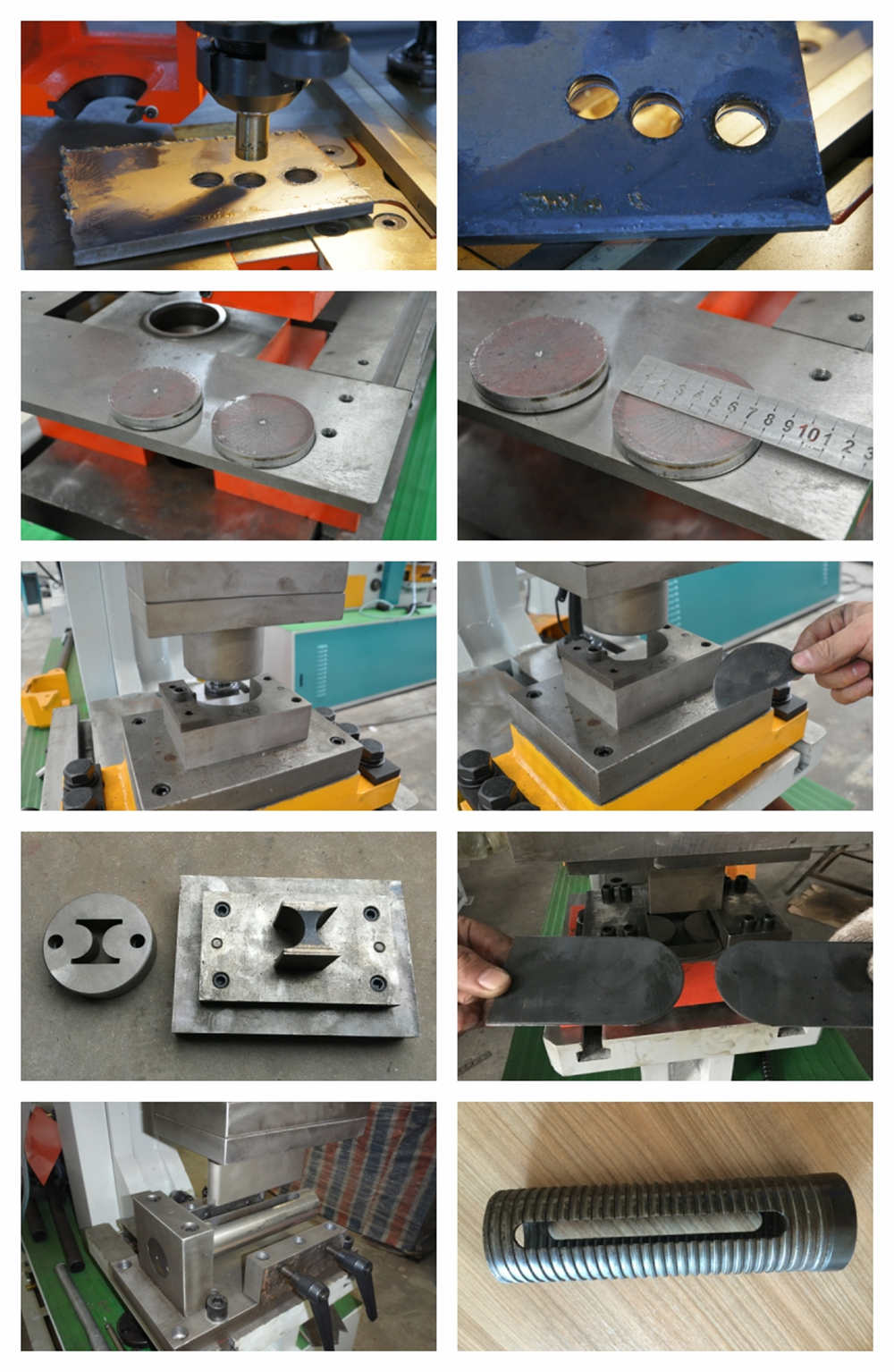

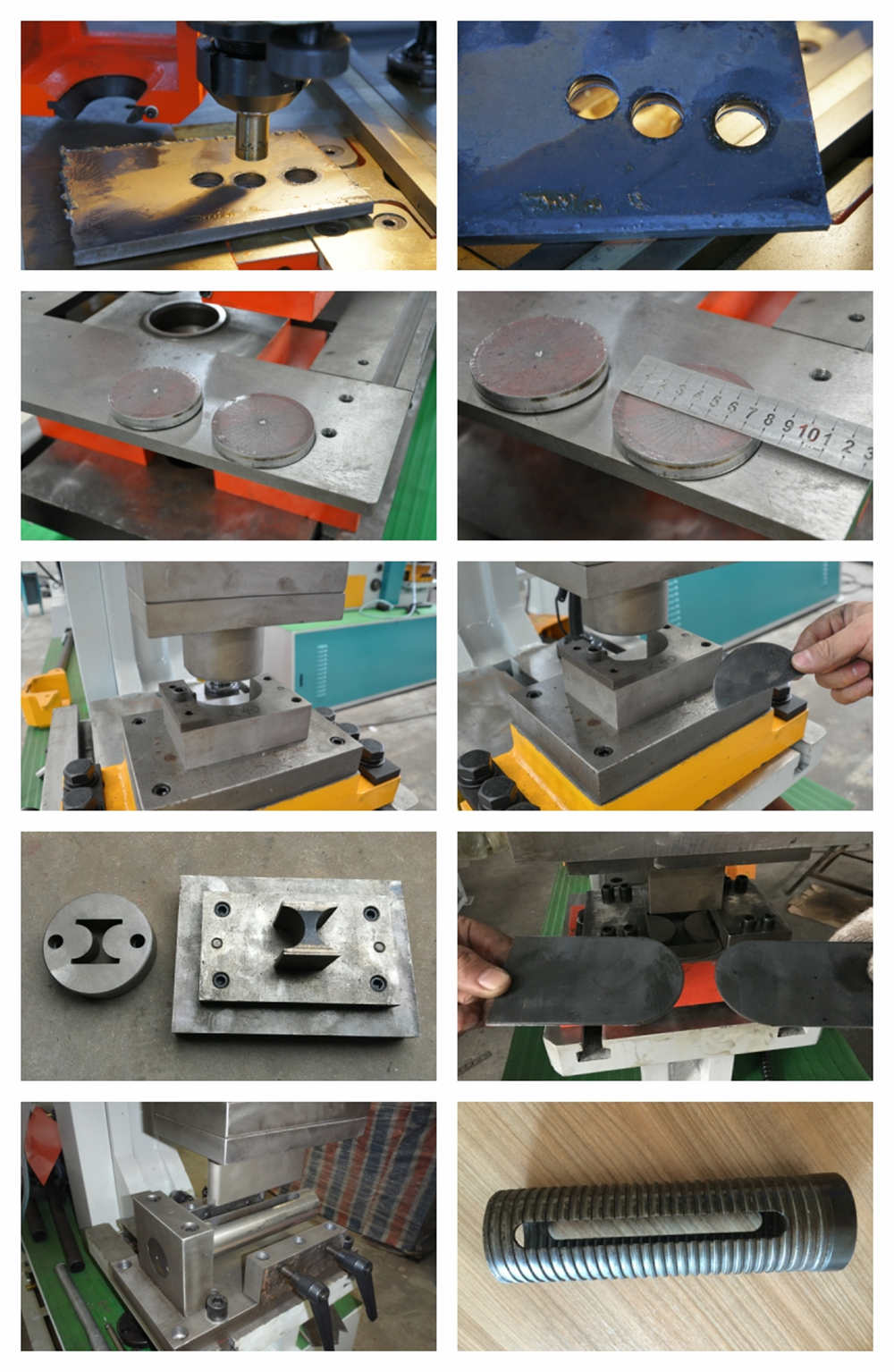

We have set up a quick change device for the punching station to replace the punch and die faster and more efficiently.

LETIPTOP has designed an automatic feeding system to cut the large size of profile steel. You can choose it according to your requirements.

Double Cylinder Ironworker Machine Features

You can set up a multi-station electric automatic back gauge to ensure repeatability of production runs.

●The strongly welded frame increases the strength of the machine.

●The foot pedal allows you to easily start and stop the Hydraulic Ironworker Machine.

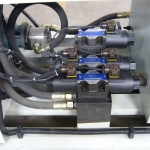

●LETIPTOP supplies an optional hydraulic holding system for the punching machine to replace the manual holding.

●If Hydraulic Ironworker Machine works for a long time, the hydraulic oil temperature will rise rapidly. LETIPTOP provides an optional cooling system for Hydraulic Ironworker Machine. When the temperature exceeds 45 degrees, the cooling system will automatically run to reduce the temperature of the hydraulic oil which will reduce the oil seal aging and extend the lifetime of the Hydraulic Ironworker Machine.

●The dual operator design allows two people to work at both ends of the machine without powering down at any one site. By having two workers use it simultaneously, you can do twice the production.

●For the 400 tons Hydraulic Ironworker Machine, LETIPTOP designed it as a split type to reduce the working height, the cost of foundation building and transportation costs for you.

●All LETIPTOP Hydraulic Ironworker Machine does not need to build the foundation. Just put it on a flat concrete floor to use it.

●2 years warranty and lifetime technical support.

Questions? Give us a call at +86-18951166013 and talk to LETIPTOP expert or email us by sales@tiptopmfg.com

Technical Parameters

.jpg)

Configuration

.jpg)

Workpiece

Workpiece

_jpg.jpg)

_jpg.jpg)

Model Selection

Punching Capacities Calculator:

Formula:

TONNAGE = (perimeter x thickness x strength)/1000

P=CxTxS/1000

P-punching pressure (Tons)

C-perimeter (mm)

T-thickness (mm)

S- material strengths(kg/mm2)

Material Strengths:

Mild Steel: 38 to 52 kg/mm2

Stainless Steel: 85 kg/mm2

Copper: 22 kg/mm2

CAUTION: Never punch a diameter smaller than the material thickness.