Double Cylinder Hydraulic Ironworker

Universal Ironworker Machine for punching, cutting, notching and bending. You also can do special workpiece after changing the molds.

●Range from 60 tons to 160 tons.

●Max punching thickness from 16mm to 30mm.

●Automatic holding system and cooling system available.

Description

Hydraulic Ironworker Description

In the past, you might need to buy a punching machine, shears, press brake, profile cutting machine and notching machine to complete the processing of various workpieces. But now it is not needed, you only need a hydraulic ironworker machine to complete all the above processing. Is it hard to imagine? Then we will introduce you to the LETIPTOP Iron Worker.

“Safety” has always been the most important for LETIPTOP. We have always been committed to the safety of the machine. So, the emergency stop switch is installed in the electrical cabinet and stations of the machine.

In an emergency, you can stop the machine at any time to prevent accidents. At the same time, the safety point is installed in the notching station. for instance,If you open the safety shield for non-safe operation, the machine does not work.

CE certification guarantees the strict quality and safety standards of the machine.

The 60-160 tons Hydraulic Ironworker Machine is a medium-sized machine. The 90 tons Iron Worker machine is the most popular. so when you choose the Hydraulic Ironworker, you can give priority to see if the 90 tons Hydraulic Ironworker Machine can meet your needs. Every year we have more than 300 sets of 90 tons Hydraulic Ironworker Machines export to 67 countries.

Ironworker Machine Features

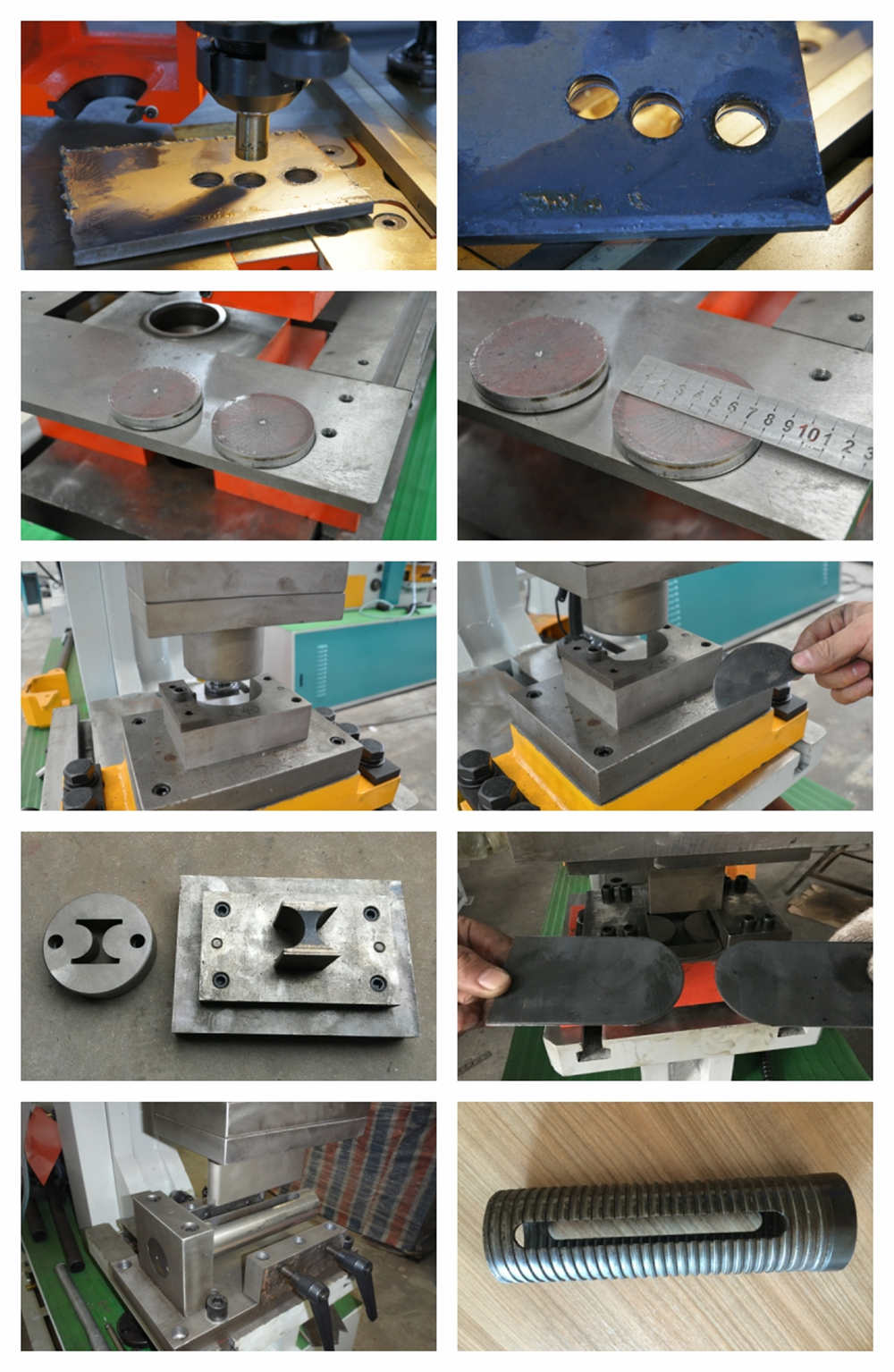

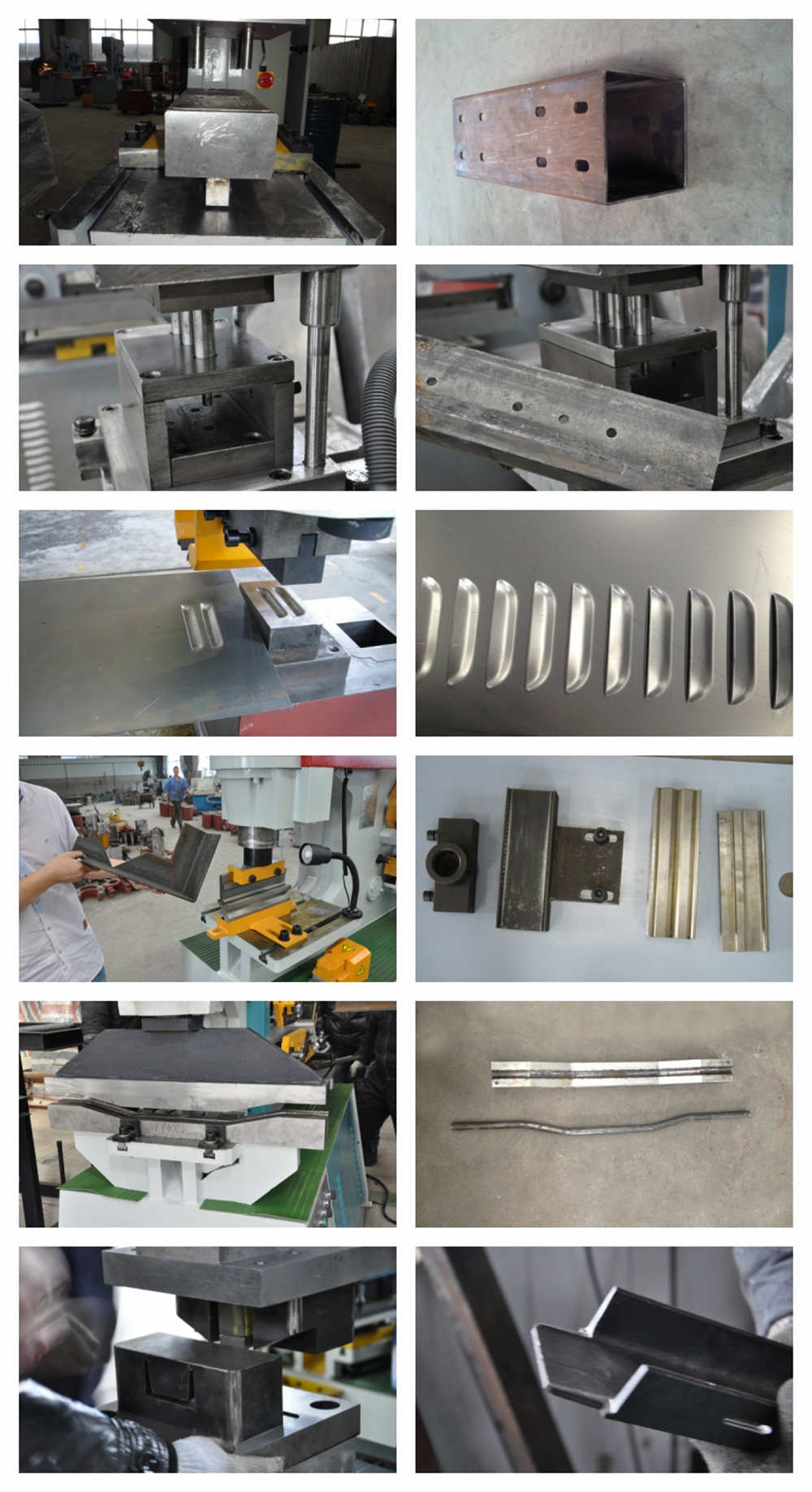

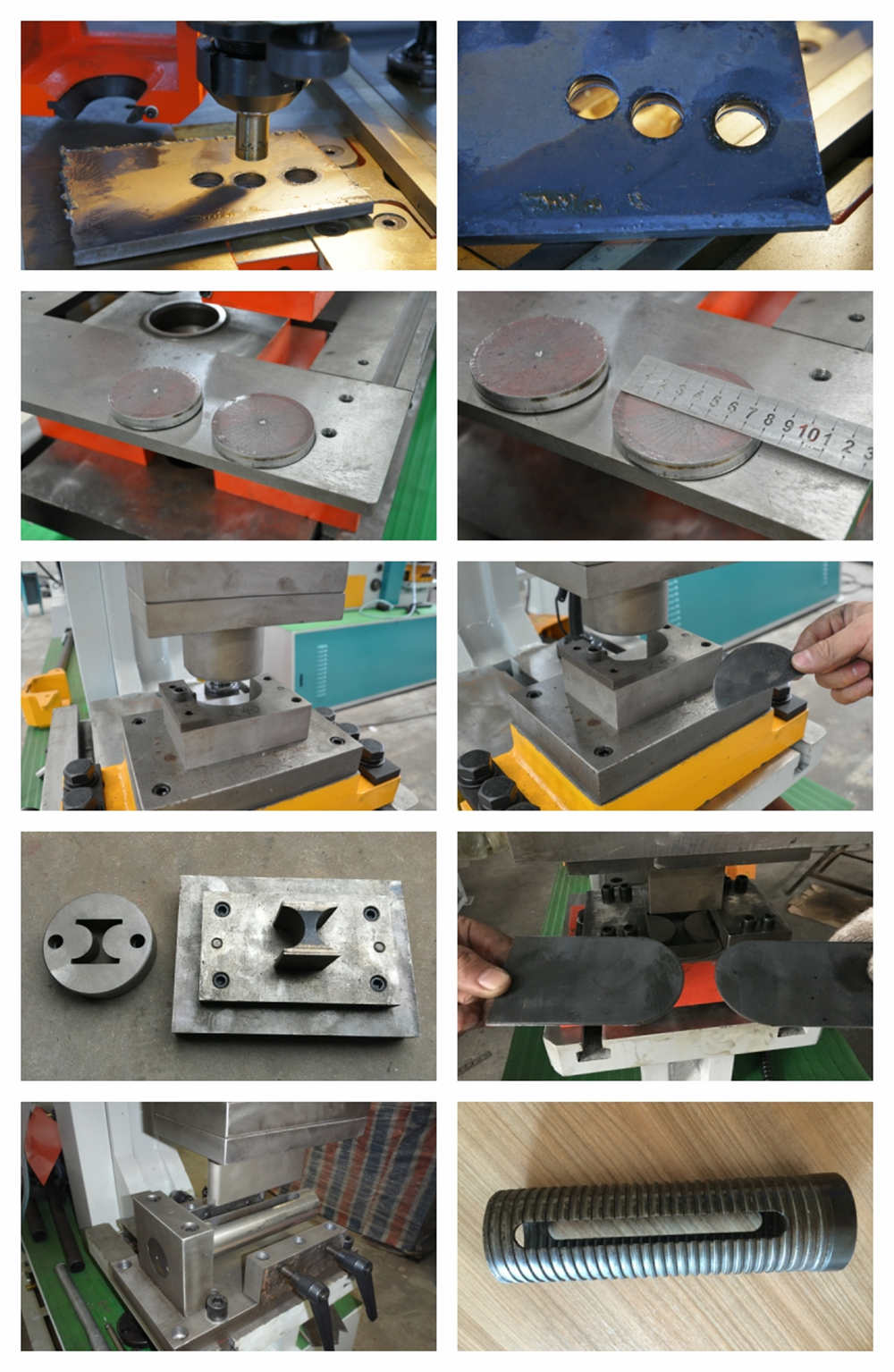

●5 working stations which including hole punching, angle steel cutting, round& square bar cutting, flat bar shearing, and notching.

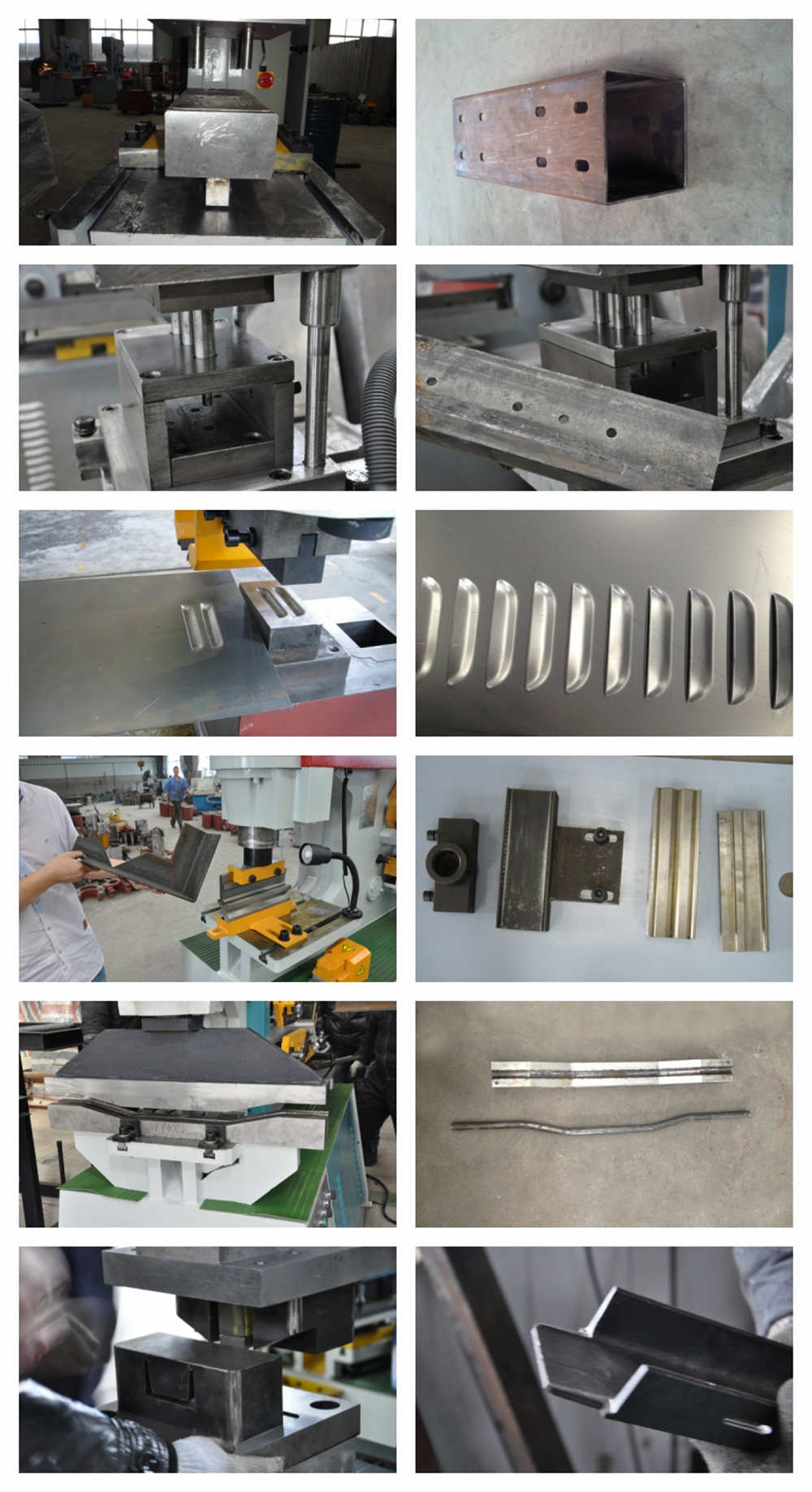

●LETIPTOP provides optional molds, which can punch different shapes of holes. angle steel punching, channel punching, I-beam punching, pipe punching, pipe notching, and joint, sheet plate bending, angle steel folding, radius corners, rounding off corners, bilateral rounding off and so on. And, In the profile cutting station, it is also possible to cut C-channel, I-beam, H-beam, T-bar and so on

●If you want to save punching time and increase work efficiency, you can adjust the punching and cutting stroke. moreover, It can punch and cut up to 22 times per minute.

●1-meter automatic back gauge for controlling the cutting length of sheet plate and profile steel.

●Manual hold-down with a knurled handle allows you to quickly fine-tune to tighten the workpiece. In order to improve efficiency, LETIPTOP has designed a hydraulic automatic holding device that holds the workpiece automatically when the footswitch is stepped on. At the same time, the LETIPTOP Ironworker Machine can also be installed two sets of hydraulic units, so that the punching station and the shearing station can be work simultaneous without being affected. This improves work efficiency.

●When LETIPTOP designed the Hydraulic Ironworker Machine, we took the use of the machine in all seasons into consideration. Especially in the summer, if the machine works for a long time, the hydraulic oil temperature will rise and the oil seal will age and leak oil. Therefore, LETIPTOP has a cooling system for it, which allows the Hydraulic Ironworker Machine to work 24 hours a day.

●Xenon work lights make it easier for workers to see the processing situation.

●2-foot pedals for control the punching station and the shearing station.

Questions? Give us a call at +86-18951166013 and talk to LETIPTOP expert or email us by sales@tiptopmfg.com

Technical Parameters

.jpg)

Configuration

.jpg)

Workpiece

Workpiece

_jpg.jpg)

_jpg.jpg)

Model Selection

Punching Capacities Calculator:

Formula:

TONNAGE = (perimeter x thickness x strength)/1000

P=CxTxS/1000

P-punching pressure (Tons)

C-perimeter (mm)

T-thickness (mm)

S- material strengths(kg/mm2)

Material Strengths:

Mild Steel: 38 to 52 kg/mm2

Stainless Steel: 85 kg/mm2

Copper: 22 kg/mm2

CAUTION: Never punch a diameter smaller than the material thickness.