Description

Description

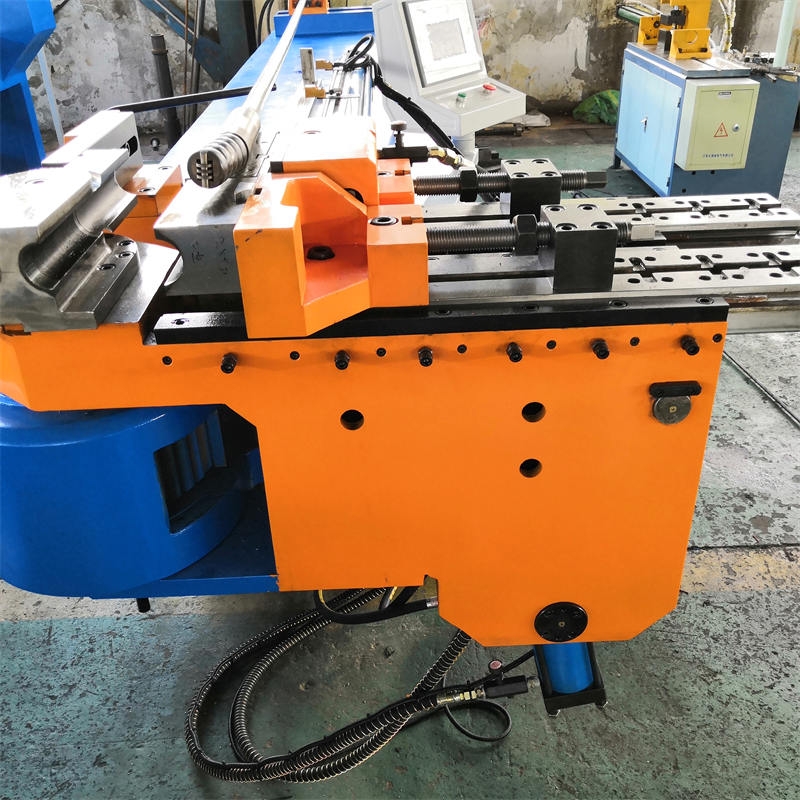

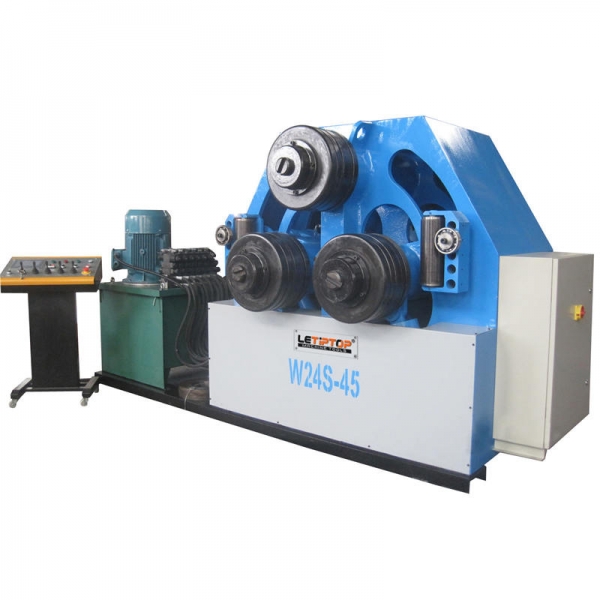

Pipe Bending Machine Description

Are you sick of outsourcing your pipe bending jobs? Are you tired of waiting up to 8 weeks or long time delivery for your jobs? Do you want more control of your own quality, inventory and lead times of your products? Then our pipe bending machine offers you good solution.

We provide a range of Hydraulic Pipe Bending Machine for bending pipes, suitable for all kinds of industries. Moreover, In order to offer quality Hydraulic Pipe Bending Machines, our quality controllers conduct stringent quality tests on every level of production. We use standard purchased components to build every tube bending machine.

Moreover, the so-called “spring back” occurring after the bending process is complete is another factor, only through overbending the workpiece compensate. This must be taken into consideration when producing the bending tool for the tube bending machine. It goes without saying that this characteristic is incorporated in the development of your custom-made tube bending machine.

Tube Bending Machine Features

●This mandrel pipe bending machine comes in many different types, from NC to CNC.

●Hydraulically driven allow for a wide range of bend radius.

●The minimum bending radius depends on the diameter of the tube but is preferably not less than 1.5D.

●The memory can store 16 programs x 16 bends, which can also be expanded later.

●The movable foot pedal switch with an emergency stop button.

●With the cooling system to control the temperature of hydraulic oil.

●High speed, high performance and high precision (+/- 0.1°).

●The optional push bending device allows the operator to bend the large radius.

●The touch screen display shows all the functions of the machine, messages, and programming in Chinese and English language.

●If display the schematic view on the machine, just touch the relevant icon square button.

●There are several modes for automatic or manual operation. (For example, whether it is necessary to use the mandrel, the auxiliary pushing, bending step by step or completed bending in once time, etc.).

●Built-in self-detection inspection system and reporting function, which showing the abnormal or false information, indicating the solution, recording the recent information for the maintenance reference.

●The user-friendly touch screen makes it easy to set up the program and can change the mold quickly.

●Multi-layer protection device ensures operator safety, manual operation or semi-automatic operation for your choice.

●Detection and indicate the error automatically to avoid damage the machine or mold.

●The perfect design for the pipe bending station allows you to have enough space for pipe bending.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the mandrel tube bending machine and talk to LETIPTOP expert.

Technical Parameters

NC Pipe Bending Machine

.jpg)

CNC Pipe Bending Machine

.jpg)

.jpg)

CNC Pipe Bending Machine

.jpg)

Configuration

.jpg)

Workpiece

Workpiece

-new.jpg)

-new.jpg)

Related products