Metal Finishing Machine

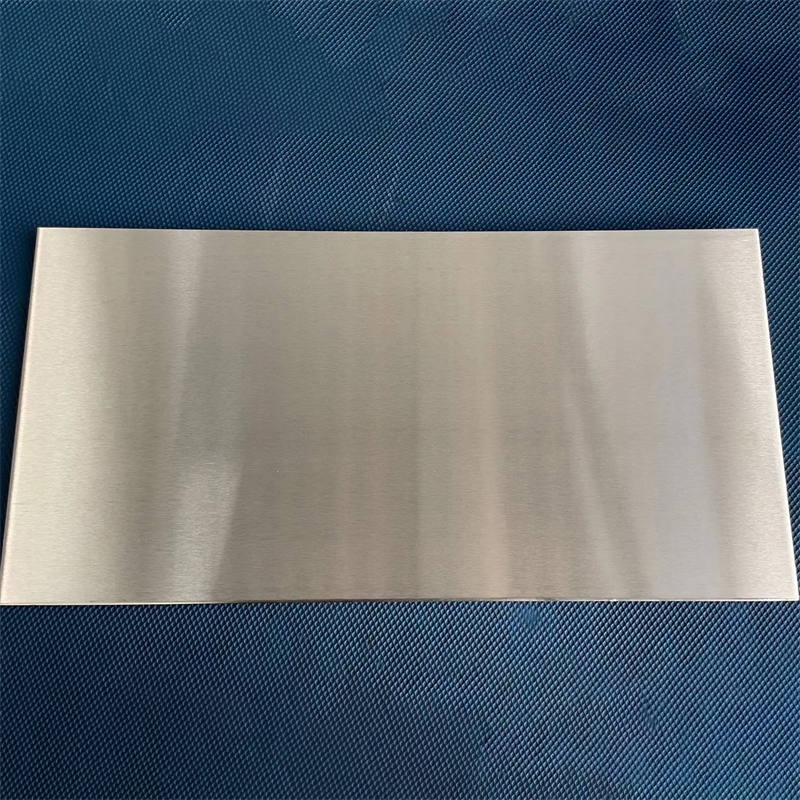

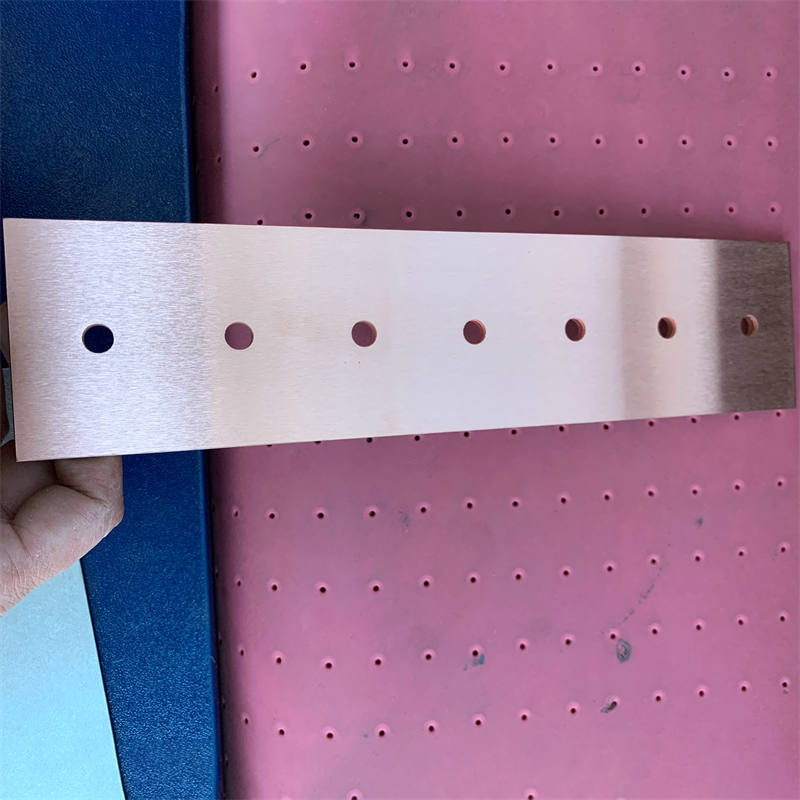

LETIPTOP Metal Finishing Machine is built with a high rigid structure which is capable of metal finishing and deburring with high standard features. It works with stainless steel, mild steel, aluminum, copper, brass and many other metal materials.

●Convenient programming controller

●2 units of abrasive belt for different usages

●Vacuum absorption system with conveyor feed table

●Dry operation mode

●Multiple processing thickness from 0.5~ 100mm

Description

Description

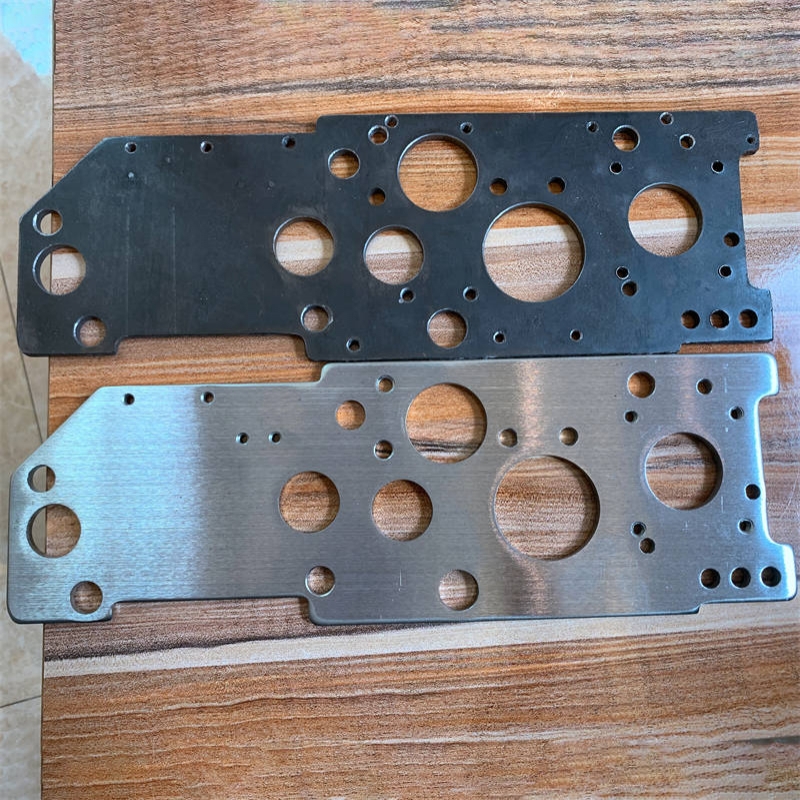

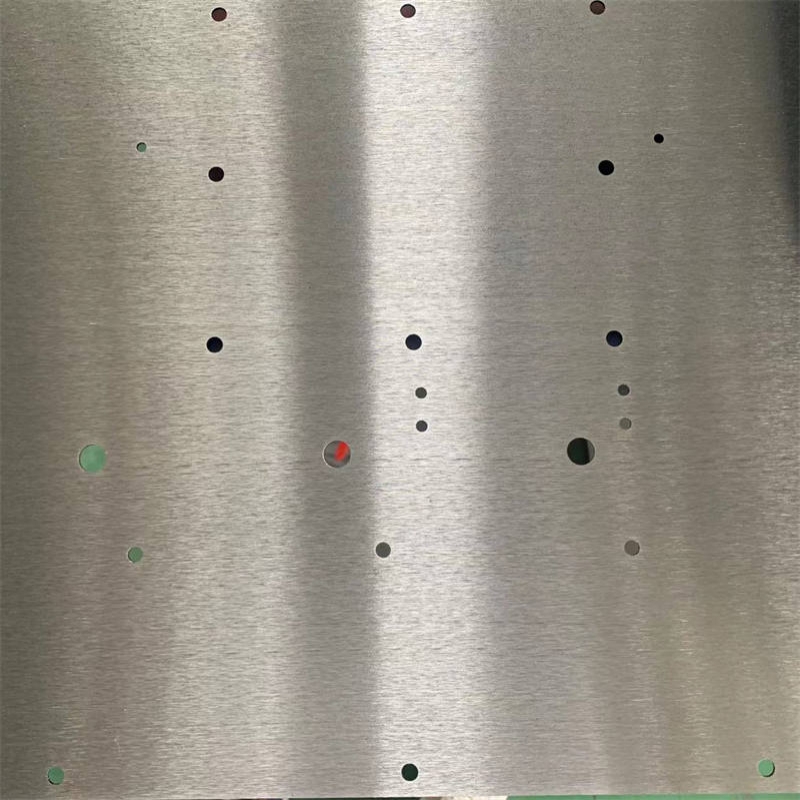

During production procedure, we always encounter burrs from laser cutting, plasma cutting, flame cutting, forging, stamping, drilling, welding. Our machine offers a variety of metal finishing solutions to meet your requirements.

LETIPTOP metal finishing machine could run safety and economically. It’s your ideal choice to achieve a uniform metal plate surface for all the working parts. Our incredible customer care center is always ready to answer all of customers’ concerning.

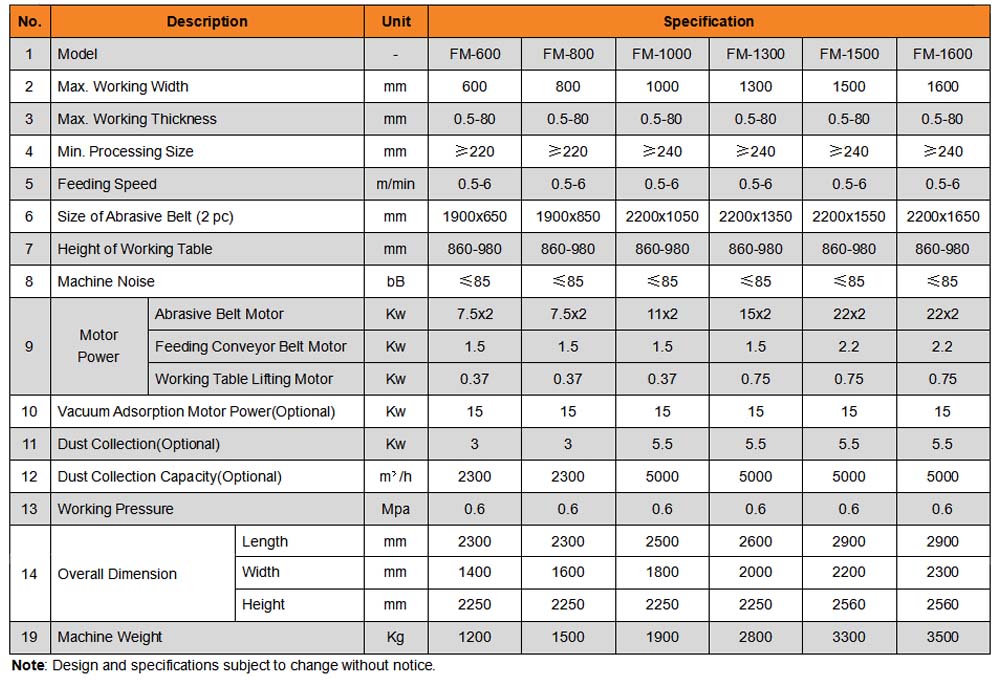

●Parts width capacity: 600mm, 800mm.1000mm, 1300mm, 1500mm and 1600mm.

●processing thickness: 100mm.

●Adjustable feeding speed

●Up to 22KW main motor drive

●Applications: Sanding, Deburring, Hairline finishing and Polishing

●Wide abrasive belt with single or multiple combination structure.

●Dust collector available with capacity 2300m³/h.

●Up to 1,000 hours of abrasive brush life.

●Directly setting of all the processing parameters.

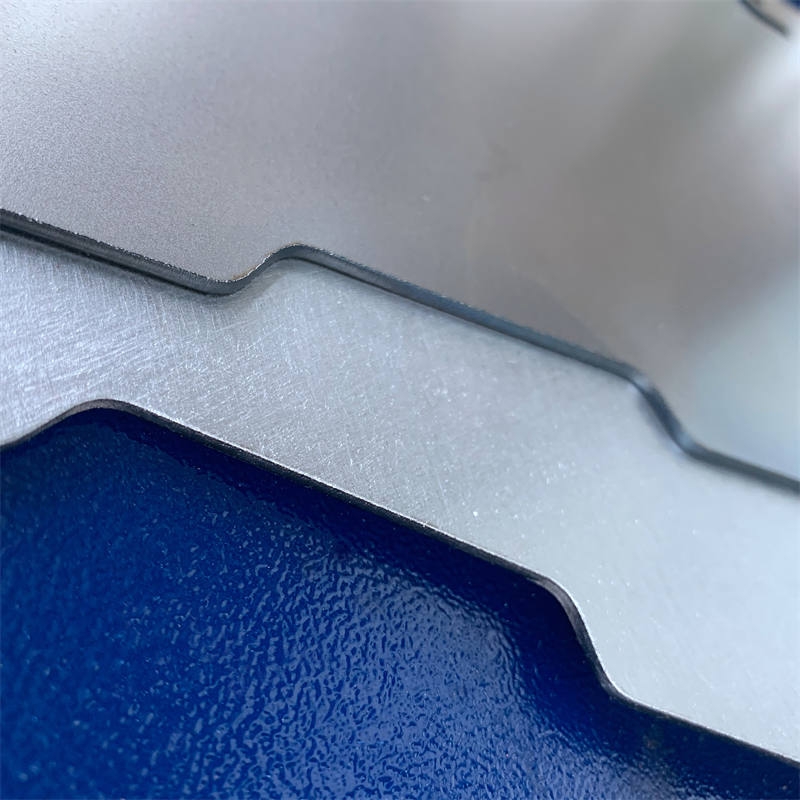

●Abrasive belt grinding station for oxide smoothing and surface finishing at one pass.

●Deburr on interior and exterior contours of the workpieces together.

●Vacuum adsorption conveyor feed table with self-cleaning air device for holding small parts.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the CNC Metal Deburring Machine and talk to LETIPTOP expert.

Technical Parameters

Function

.jpg)

Workpiece

Workpiece

.jpg)

.jpg)

Related products