Deslagging Deburring Machine

LETIPTOP Slag removal Finishing and Deburring Machine is a heavy duty type machine designed especially for deburring, heavy slag removing, edge radiusing, laser oxide removal, grinding and polishingin a single pass.

●Working width of 1000mm and 1300mm

●Comprehensive deburring and deslagging procedure

●Top brand PLC touchscreen controller

●With hammer head

●Sand belt Correction Photoelectric Sensor for precise processing

Description

Description

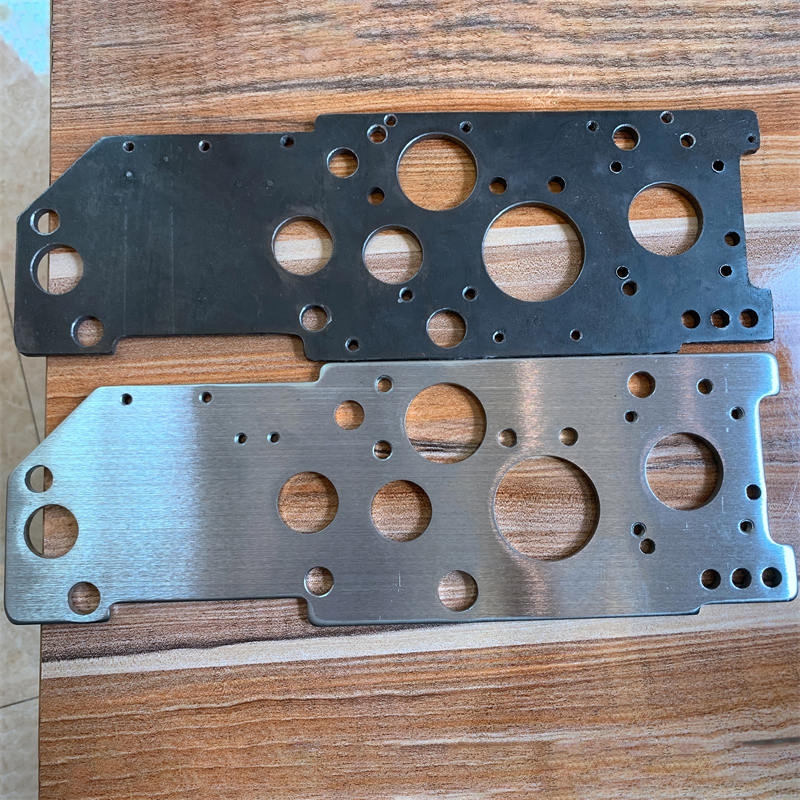

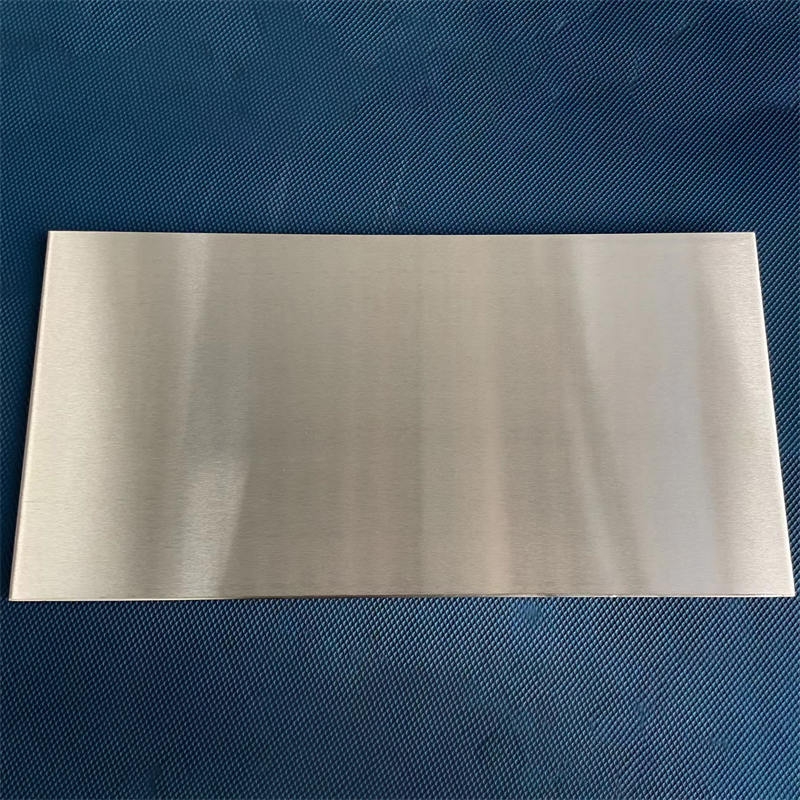

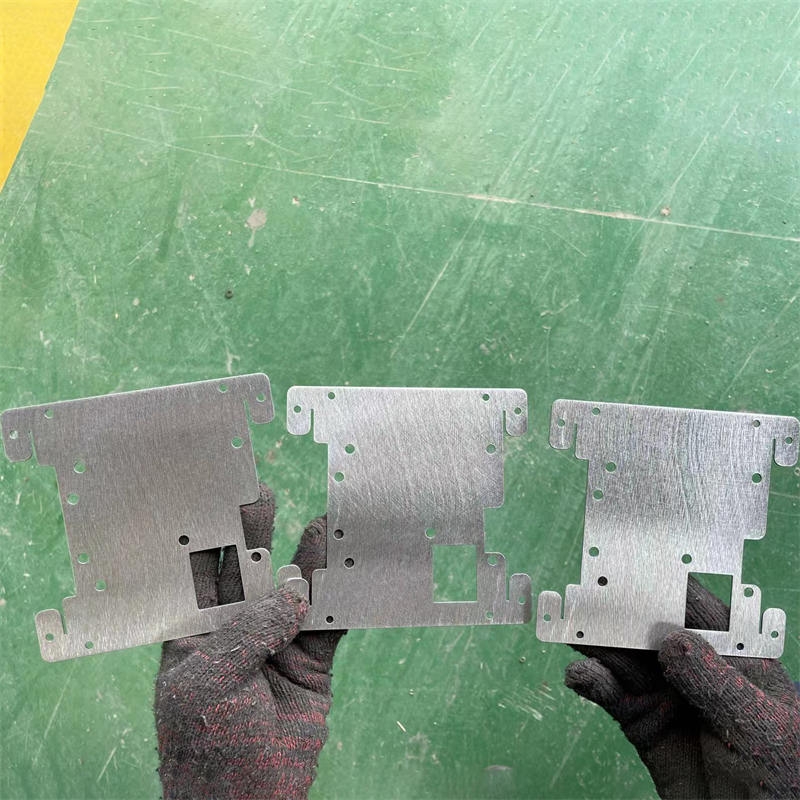

In order to meet customers’ requirements on heavy dross slag removing, we launched LETIPTOP Slag removal finishing and deburring series machine. It’s suitable for steel parts deburring, slag removing, edge rounding, chamfering, finishing and grinding or combination of these applications.

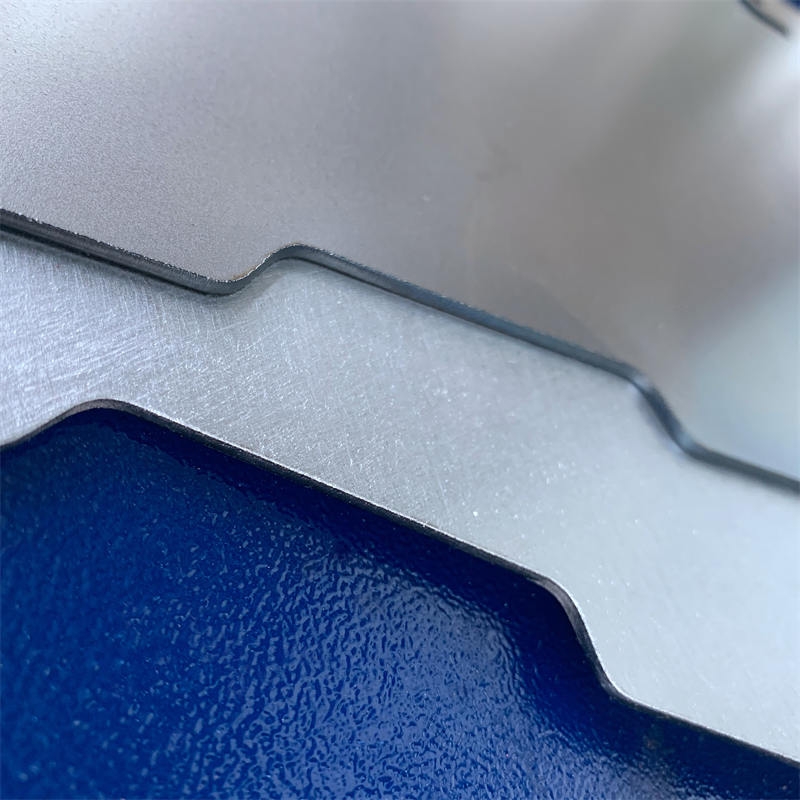

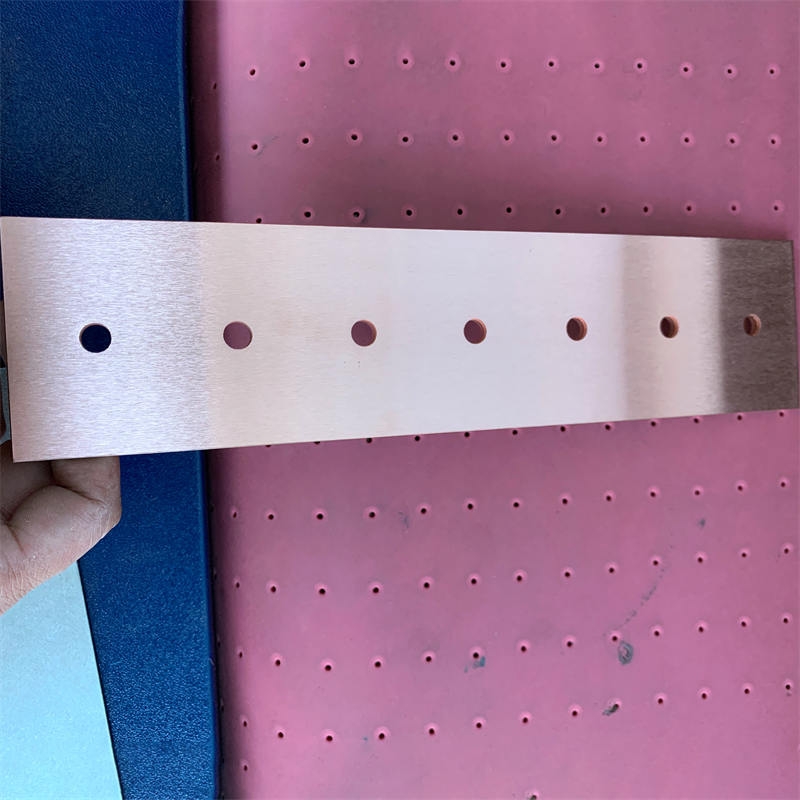

LETIPTOP Slag removal finishing and deburring machine is equipped with a hammerhead which can remove slag dross causing by punching, laser and plasma cutting, stamping, drilling and forging. The machine is cost-effective with high productivity.

●High rigid structure frame

●Wide abrasive belt and de-slagging unit to remove heavy dross slag

●Adjustable feeding speed

●Dust collector available with capacity 2300m³/h.

●Up to 1,000 hours of abrasive brush life.

●Suitable for various metal parts: stainless steel, aluminum, alloy steel etc.

●Abrasive belt grinding station for oxide smoothing and surface finishing at one pass.

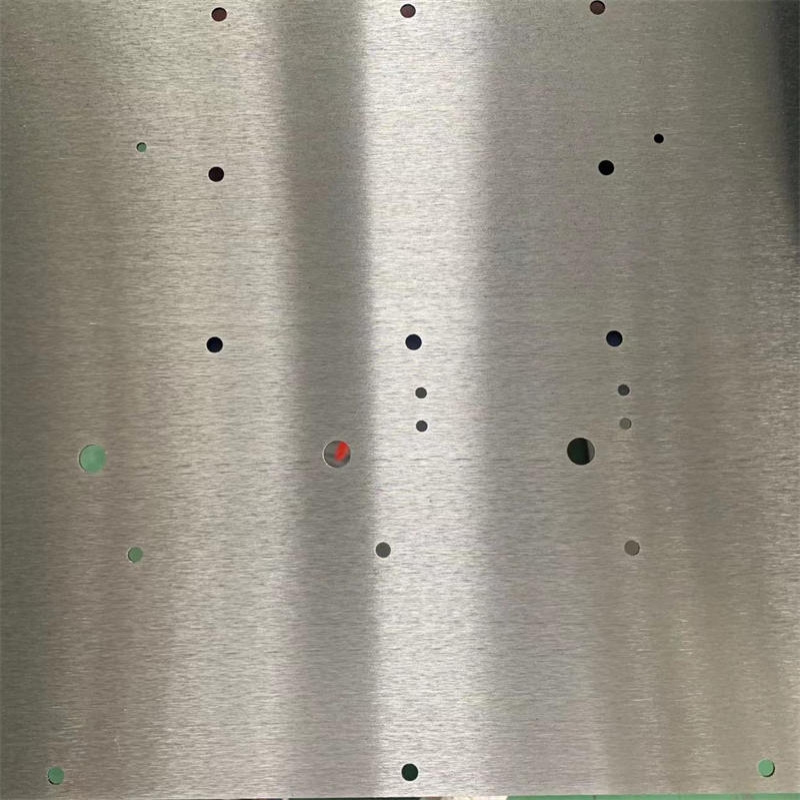

●It is fully automated to grind heavy steel plates without scrap left

●Sand belt Correction Photoelectric Sensor to ensure belt alignment during processing.

●Touchscreen controller for easy operation

●Customized configurations available for a variety of applications

●Vacuum adsorption conveyor feed table with self-cleaning air device for holding small parts.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the CNC Metal Deburring Machine and talk to LETIPTOP exper

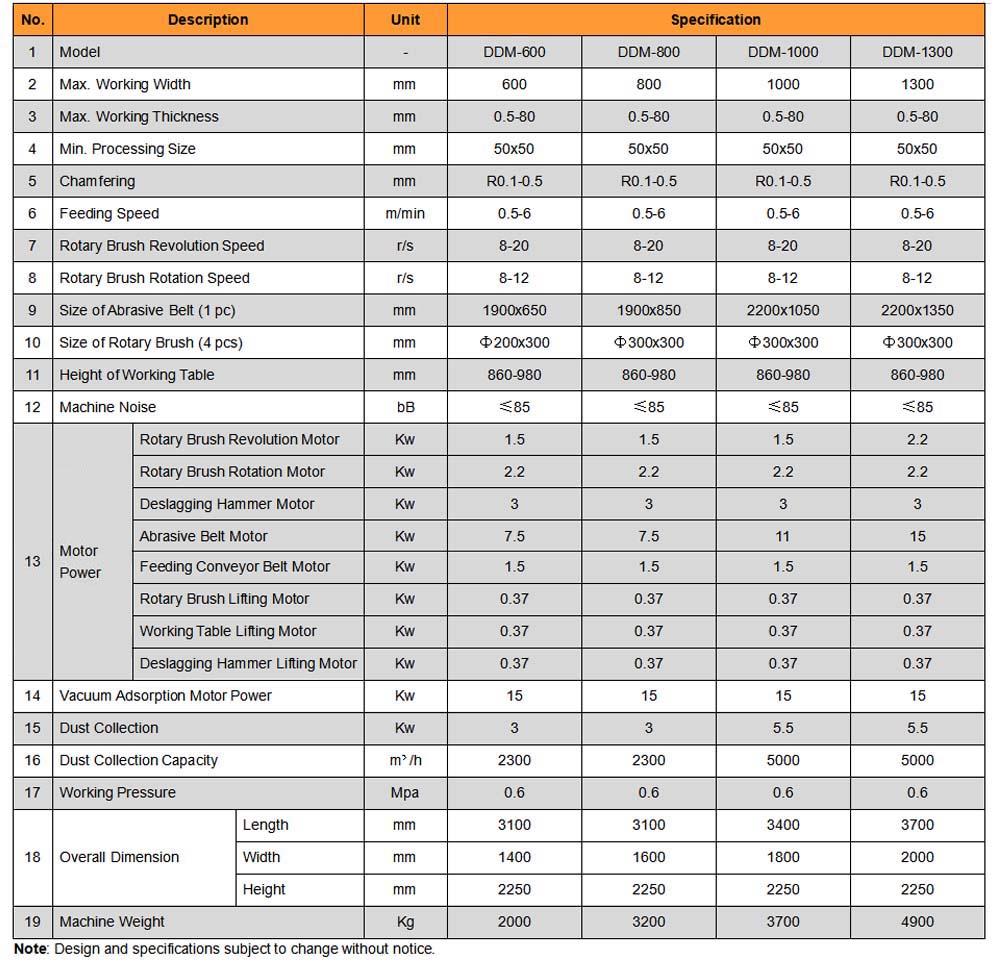

Technical Parameters

Function

.jpg)

Workpiece

Workpiece

.jpg)

Related products