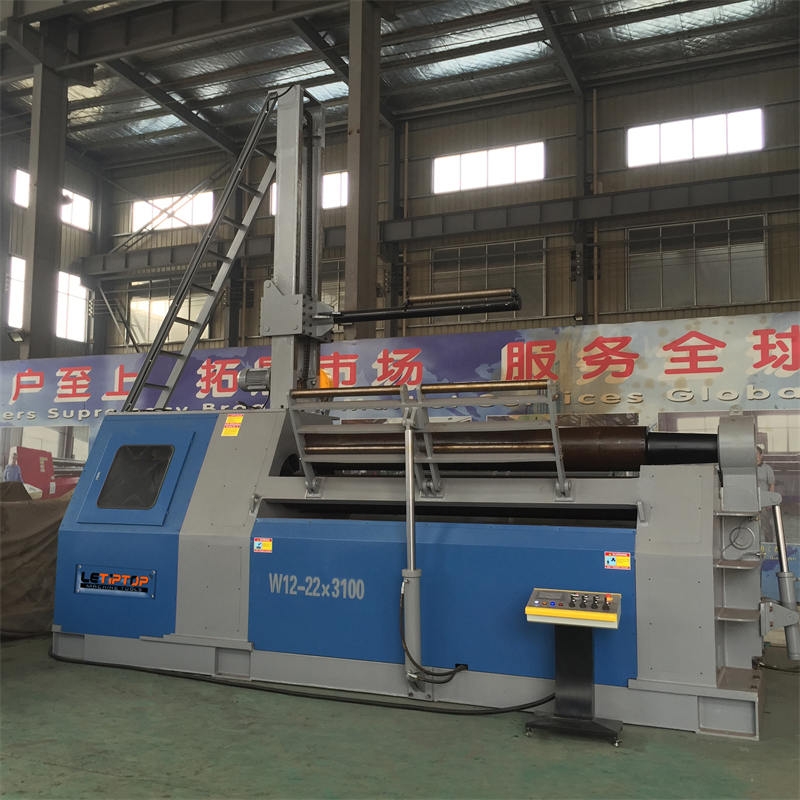

W12 series 4-Roller Hydraulic Plate Rolling Machine

LETIPTOP 4-roller plate rolling machine is advanced plate bending and rolling machines. They are available in rolling O-shape, U-shaped, multi-section R-shape with high precise.

●4 rollers plate rolling machine.

●Hydraulic type.

●CNC type.

●Cylindrical shape, circular arc shape and conical shape rolling.

Description

Description

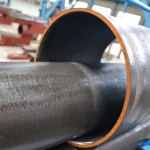

Plate Rolling Machine Description

Our 4-roller plate rolling machine is advanced plate bending and rolling machines because they are more precise, efficient, flexible, faster, safer and easier to operate.

They are available in rolling O-shape, U-shaped, multi-section R-shape and so on. It is an ideal model for rolling workpieces in industries such as energy, transportation, petroleum, chemical, boiler, shipbuilding, hydropower, and metal structures. 4-roller plate rolling machine create a higher return on investment, saving time and cost.

Hydraulic Rolling Machine Features

●CNC control, digital display for the position of each roller. High accuracy and precision circle.

●With pre-bending function at the end of the plate, which can feed the metal sheet plate once. It can complete the pre-bending of the plate end and the rolling the workpiece without turning the metal sheet plate.

●4 hardening rollers (HRC 58). The working roller is the main driving roller. The bottom roller and both side roller are hydraulically driven. The computer controls the lifting.

●The rolls can be a coating for rolling stainless steel. It does not damage the stainless steel surface.

●The rear part of the upper roller is equipped with a balance mechanism, which can easily unload the rolled workpiece.

●The movable control panel unit with an emergency stop switch.

●The programmable CNC control system can store automatic rolling data for more than hundreds of different workpieces. It enables one-click choosing and one-button startup. Automatic workpiece rolling without manual operation.

●The system has the function of interlocking and interconnection protection measures to prevent misoperation.

●The operating system has the function of EPS electronic automatic leveling system, which can automatically adjust the parallelism of the rollers to ensure product quality.

●The material setting, pre-bending, and rolling steps can be completed in the rolling process. The remaining straight edge length for pre-bending is ≤1.5 times the thickness of the plate. High precision rolling can meet the requirements of automatic welding.

●The optional hydraulic crane and hydraulic lateral support can effectively control the workpiece deformation in the rolling due to the workpiece self-weight.

●The optional cone-rolling device can meet customer needs to roll conical shape.

●It is not only for a cylinder rolling but also for arc shape, square shape, triangle shape, oblate shape, and oval shape.

●This model not only satisfies the circular cylindrical shape rolling process but also can satisfy the automatic rolling of arc, square, triangle, oblate, elliptical and other shape workpieces.

●2 years warranty and lifetime technical support.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the plate rolling machine and talk to LETIPTOP expert.

Technical Parameters

.jpg)

Configuration

.jpg)

Working Principle

Working Principle

.jpg)

.jpg)

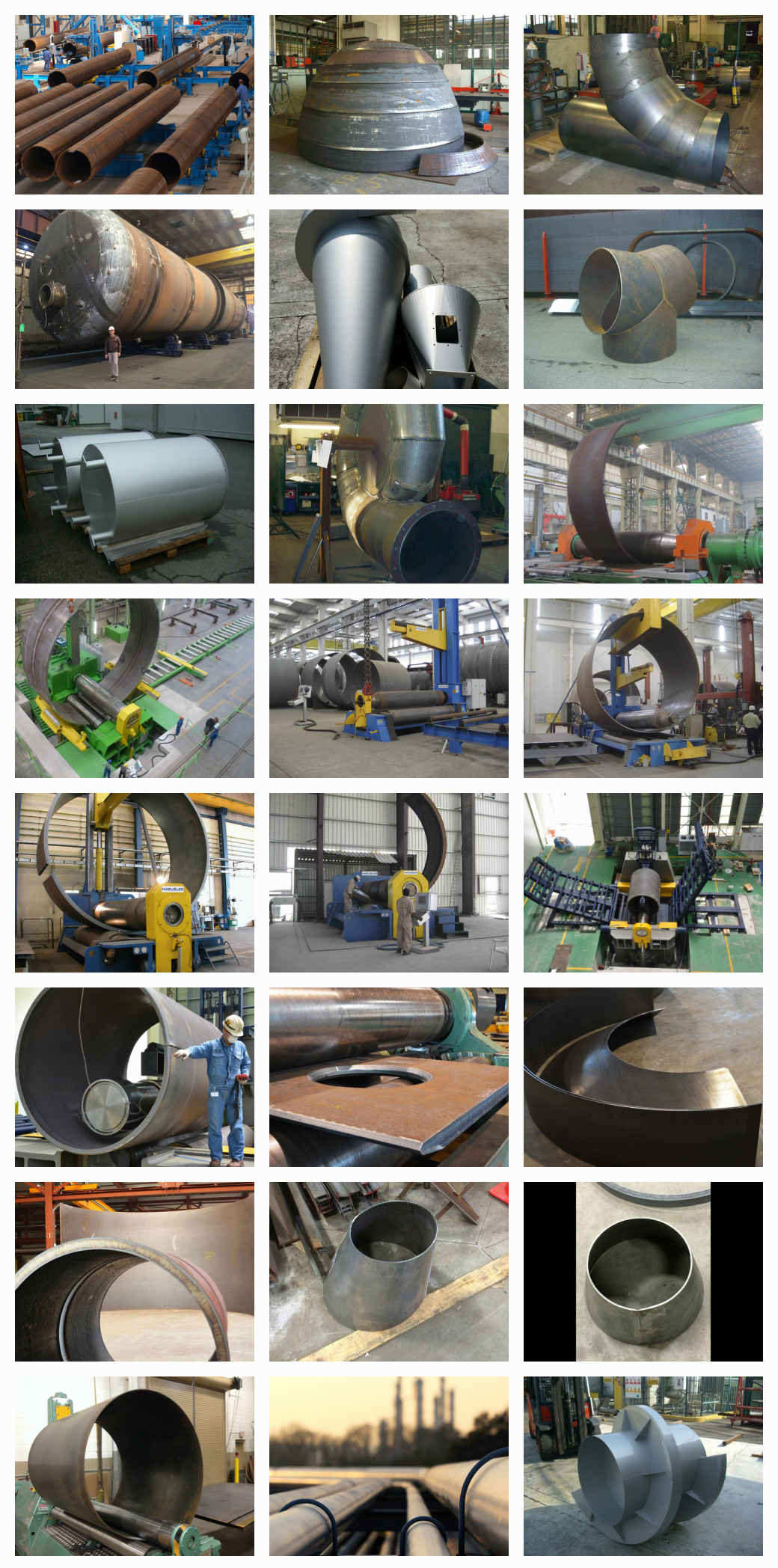

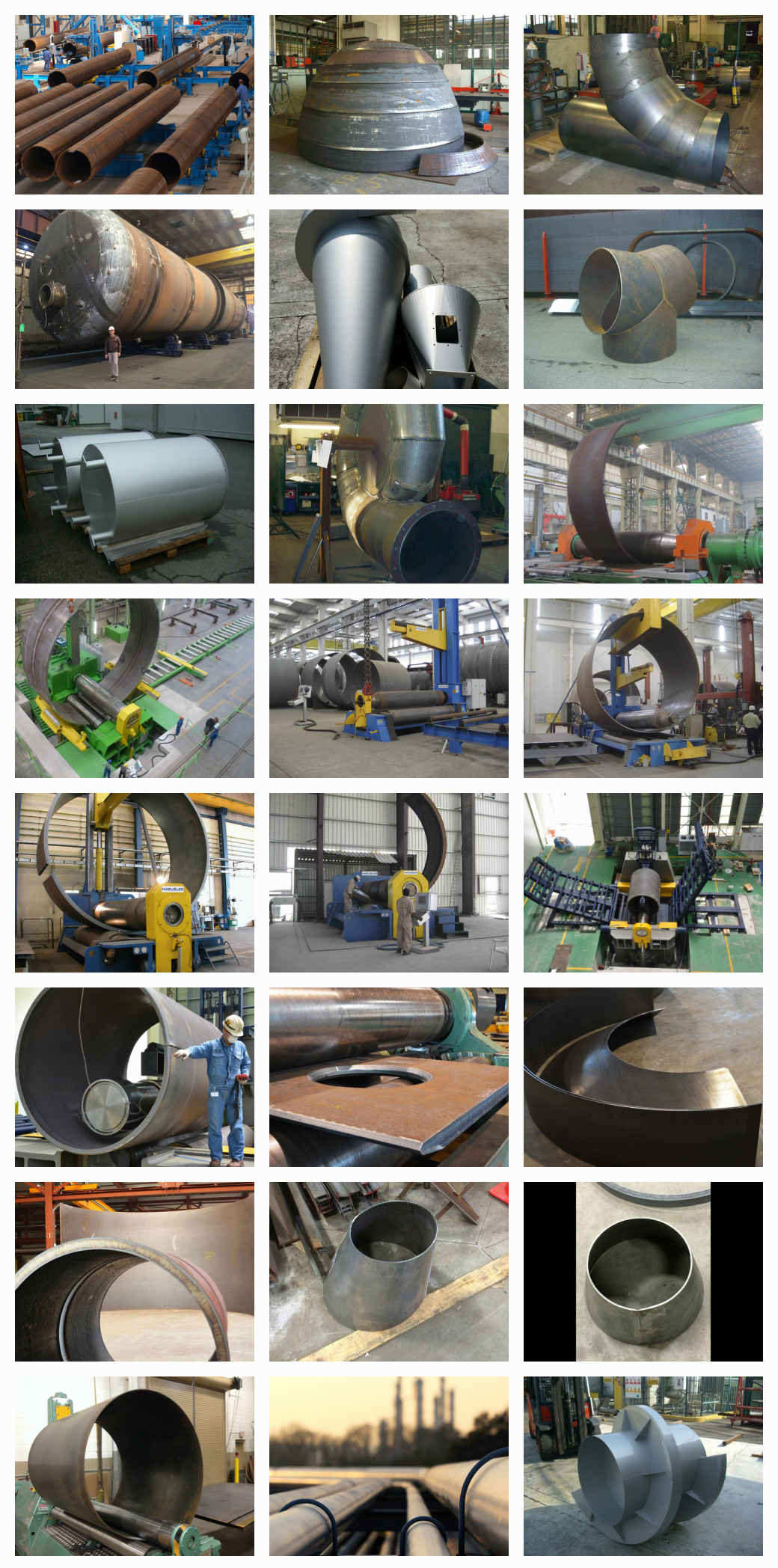

Workpiece

Workpiece