CNC Press Brake

Description

Description

CNC Press Brake Description

LETIPTOP CNC Press Brake provides superior performance and bending solutions to meet customer needs. It can make your workshop less investment, high production efficiency and more economical.

If your workshop doesn’t have enough places for the press brake, we can customize the small size bending machine for you. It can also be used at home.

Our heavy-duty press brake wildly uses in every industry. Such as shipbuilding, infrastructure infra, transportation, steel structure, wind turbines, power plants, national defense, etc.

The wide range of press brakes LETIPTOP varies by working force, size and production capacity.

CNC Press Brake Features

●Pendant controller arm unit with Delem DA52 CNC control system which can program according to the bending requirements. 6.4” LCD TFT color display

●Movable foot pedal switch with an emergency stop button to control the up and down movement of the cylinders.

●Optional light curtains ensure operator safety.

●Fast clamping device on the upper punch, which is convenient and quick to change the upper punch.

●The segmented upper punch can be used to bend workpieces with various widths.

●Multi-V bottom dies for workpiece bending at various angles.

●The slider fast down speeds up to 200mm/s.

●The integrated hydraulic system receiving rapid approach switching automatically to slow bend

●The nylon front support can prevent to scrap the sheet plate and improve the process level.

●The servo drive back gauge precisely controls the bending length. With the R axis, the back gauge can move up and down.

●Standard 3+1 axis, Y1, Y2, X, R+V.

●Hydraulic crowning system or mechanical compensation for choice.

●The working table is equipped with the anti-deflection system.

●Motorized back gauge rides on a solid ball screw and linear guide rail.

●The back gauge finger moves smoothly on the linear guide, which is convenient, efficient and easy to control.

●Electrical cabinet with open door and power of the device.

●The air cooling system can reduce the oil temperature, prevents oil seal aging and oil leakage, and improves the lifetime of the machine.

●In poor lighting conditions, working light can be used.

●Oil tank level indicator.

●Rear and side safety protection guard. The rear protection guard can be a safety light curtain or safety door, and the corresponding safety detection device should be connected to the safety control system;

●2 years warranty and lifetime technical support.

Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com today for a formal quote on the press brake machine and talk to LETIPTOP expert.

Technical Parameters

.jpg)

Configuration

.jpg)

Model Selection

Model Selection

Plate Bending Pressure Calculation:

Calculation Formula:

P=S²x 65 x L/V

S-the thickness of plate

L-the width of plate

V-the width of the slot of bottom die

Note: The formula is based on carbon steel plate with tensile strength 45kg/mm2

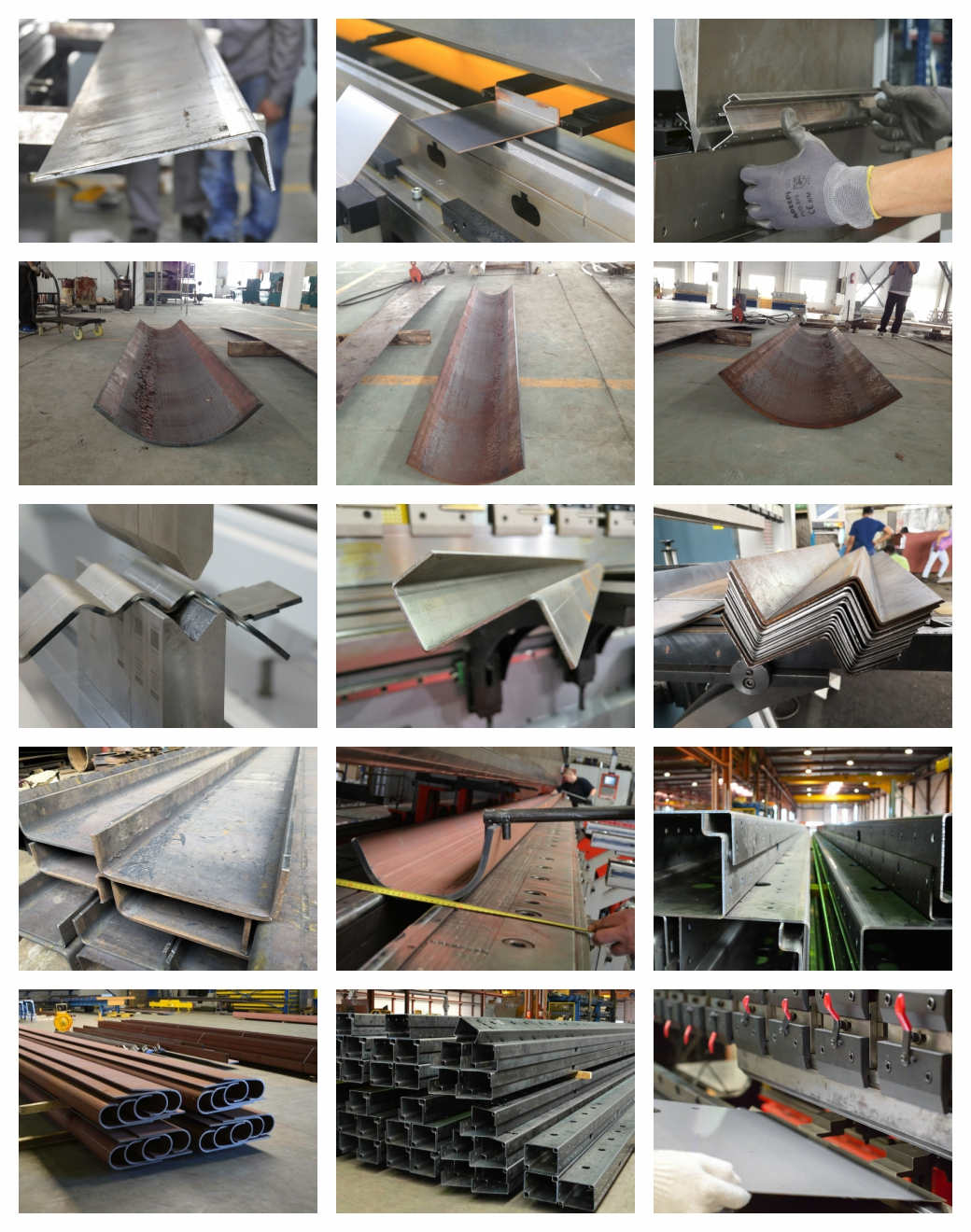

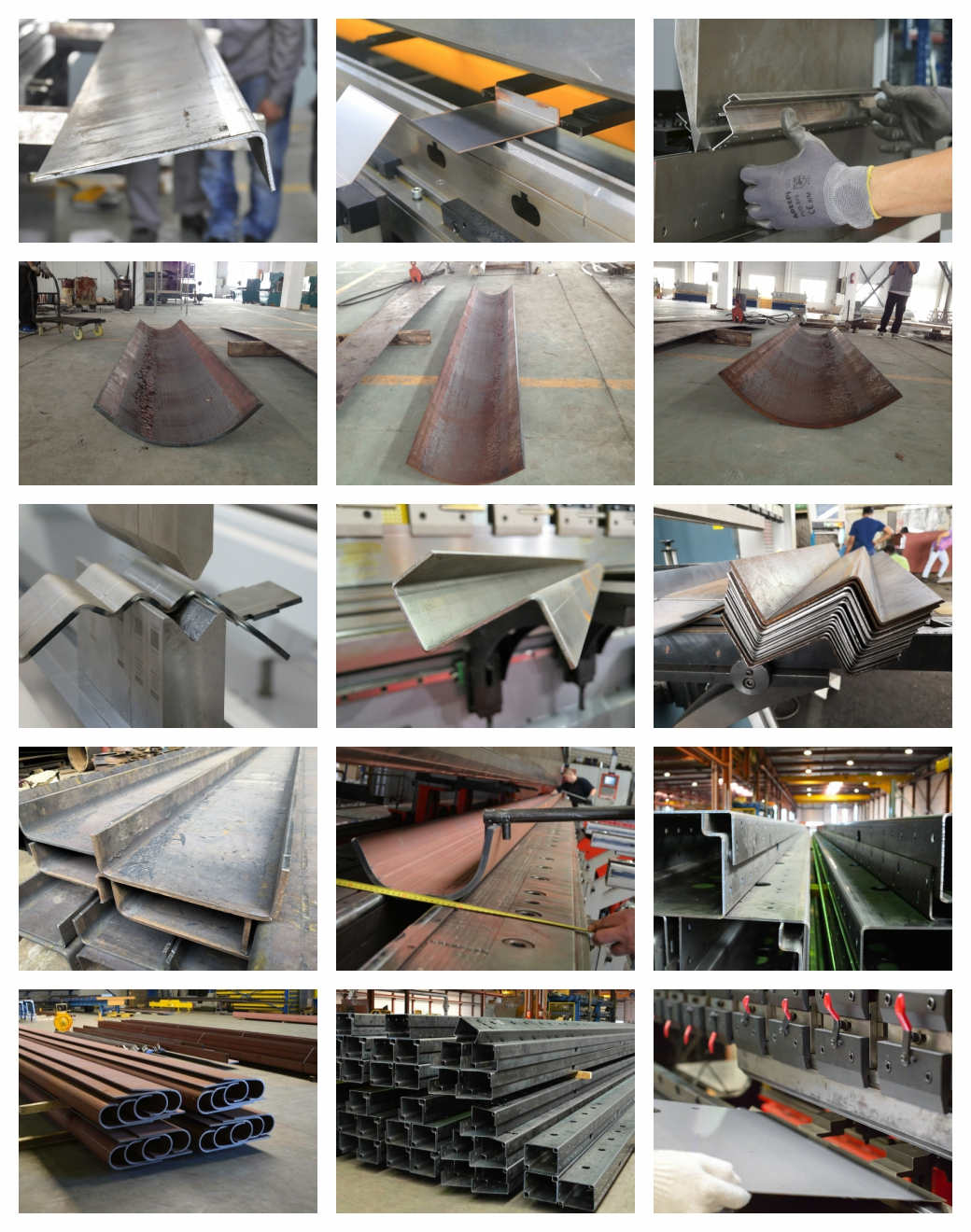

Workpiece

Workpiece

Related products