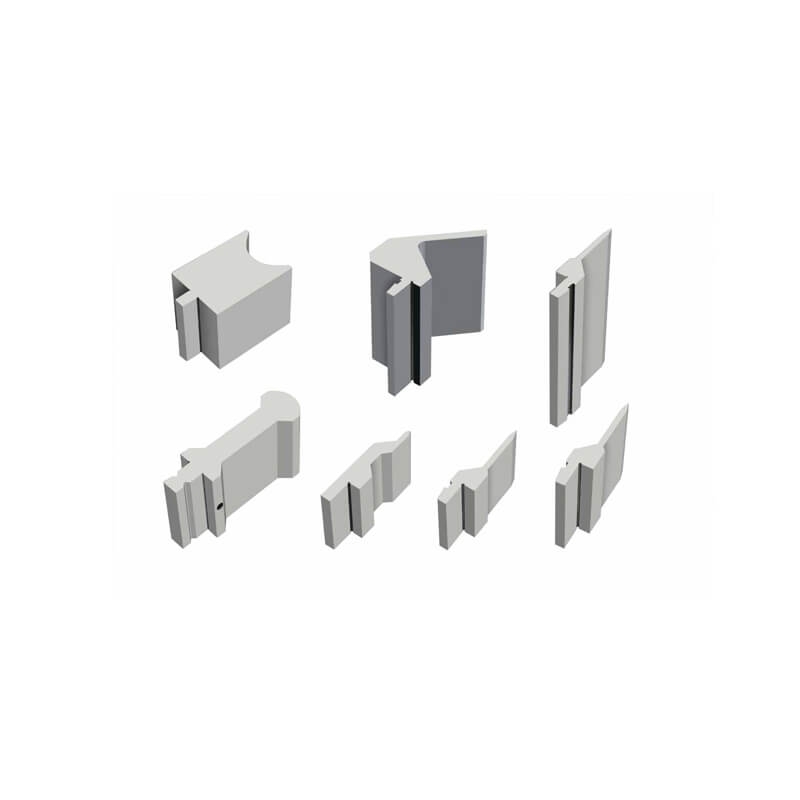

Press Brake Tooling

LETIPTOP design special press brake tooling for different jobs. For example Variety angle bending or edge bending.

●Variety material for press brake tooling.

●Quench hardened upto HRC 52°-56°.

●Tolerance upto ±0.002.

●Segmentation press brake tooling available.

Description

Description

Press Brake Tooling Description

The Press Brake Tooling is divided into the upper punch and bottom die, which for sheet metal bending and separation. The mold for bending has a cavity, and the mold for separation has a cutting edge.

In general, we use the material 42CrMo, 9CrSi, T8, T10, 6CrW2Si, Cr12MoV (SKD11), H13K, HMB, W18Cr4V, LD, W6Mo4V2, W18Cr4V to make the bending dies. Those materials have high density and wear resistance

CNC Press Brake molds Features

●Quench hardened: HRC 52°-56°

●Tolerance: ±0.002

●Standard length: 835mm, 800mm, 550mm

●The standard CNC Press Brake molds are available in stock. The non-standard Press Brake molds can be customized according to the drawings provided by customers.

●CNC Press Brake Tooling are segmented. The general segmentation specifications as follows:

●Segmentation 1

●Upper Punch: 100 (left), 10, 15, 20, 40, 50, 200, 300, 100 (right) = 835mm

●Bottom Die: 10, 15, 20, 40, 50, 100, 200, 400 = 835mm

●Segmentation 2

●Upper Punch: 100 (left), 10, 15, 20, 40, 50, 165, 300, 100 (right) = 800mm

Press Brake Tooling Requirements? Give us a call at +86-18951166013 and talk to LETIPTOP expert or email us by sales@tiptopmfg.com

Moulds OEM

Moulds OEM

.jpg)

.jpg)

Related products